The T8 Controller: The Brain of the Embroidery Machine

Section outline

-

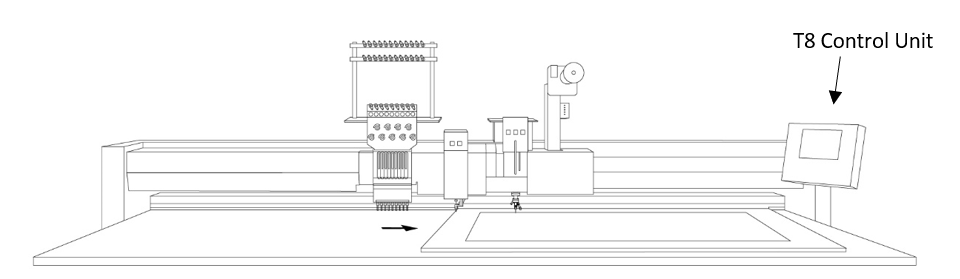

The T8 Controller: The Brain of the Embroidery MachineIn the embroidery process, digital design files are loaded into the machine’s controller—known as the T8 Control Terminal—either via a network connection or by inserting a USB drive.

Before embroidery begins, the operator uses the T8’s built-in touchscreen to review the loaded design. They can check the layout, set design parameters, adjust stitch start points, and confirm that everything is correct before initiating production.

How the T8 Communicates with the MachineOnce embroidery is started, the pantograph and embroidery heads no longer act independently—they continuously receive real-time commands from the T8.

The T8 sends highly detailed instructions to the embroidery machine’s internal computer systems, which in turn direct the servo motors that drive the pantograph’s X and Y movement.

Key functions coordinated by the T8 during embroidery include:

- Precise control of frame movement (X and Y axes)

- Timing and synchronization of needle up/down motion

- Adaptive speed control based on the geometry of the design

- Real-time compensation for inertia changes caused by different frame or material weights

This means that simple, straight-line running stitches can be executed at very high speeds, while complex corners, tight curves, or fine details automatically trigger the machine to slow down for maximum precision—all without requiring any manual intervention.

The T8 is Like the CNC Controller of EmbroideryIn many ways, the T8 Control Terminal functions similarly to a modern CNC (Computer Numerical Control) machine interface.

Just like a CNC machine reads a toolpath file (such as a G-code program) and converts it into movements of motors and mechanical components, the T8 reads an embroidery design file (typically in .DST, .DSB, or similar formats) and orchestrates every motion needed to execute it perfectly.

Instead of moving a milling head or laser nozzle, the T8 moves:

- The embroidery frame (through pantograph control)

- The embroidery needle (up and down with precise timing)

- Specialty attachments (like cutting devices, fiber placers, or cording modules)

The T8 is not just a storage unit—it's a live, intelligent system actively managing motion, timing, material interaction, and feedback throughout the embroidery process.

Why Firmware Updates MatterBecause the T8 is a sophisticated control computer, its performance depends heavily on its internal software—known as firmware.

Manufacturers like ZSK continuously improve firmware to:

- Optimize speed and precision for new embroidery techniques

- Fix minor bugs or compatibility issues with new design file types

- Improve user interface features and workflows

- Enhance motor control algorithms for even smoother, faster embroidery

- Introduce support for new attachments and expanded capabilities

Therefore, it is highly recommended to keep your T8 firmware updated regularly. Updating firmware ensures your machine runs at peak efficiency, reduces the risk of system errors, and unlocks the latest features developed for technical embroidery innovation.

At ZSK Academy, we train all users on how to properly update and maintain their T8 units, helping you keep your embroidery operation at the cutting edge of performance.

Summary: The Nerve Center of PrecisionThe T8 Controller is the nerve center of every ZSK technical embroidery machine. It is the critical interface between your digital design and the physical movement of the embroidery process.

Understanding and maintaining your T8 is not just a matter of convenience—it’s essential for achieving the highest levels of precision, efficiency, and innovation in technical embroidery.

Smart designs need a smart controller—and the T8 delivers.