Understanding Embroidery Heads: The Core of Technical Embroidery

Section outline

-

In technical embroidery, embroidery heads are the heart of the machine. Each embroidery head is an individual embroidery station equipped with its own set of needles, attachments, and functional components, capable of producing designs independently. These heads are where the magic happens—where thread, wire, fiber optics, and advanced materials are precisely laid down to create everything from decorative patterns to highly engineered functional textiles.

Each head operates as a dedicated workstation, executing a specific design or sequence according to the programmed instructions. Depending on the type of head and its setup, it can stitch traditional thread, lay down technical fibers, insert functional components, or even build multi-material assemblies directly onto a base fabric or substrate.

What is a Multi-Head Embroidery Machine?

When multiple heads are combined into a single machine frame, you get a multi-head embroidery machine. In multi-head systems, several embroidery stations work simultaneously, vastly increasing production capacity and efficiency.

For example:

-

A two-head machine can embroider two identical designs at once, cutting production time in half compared to a single-head machine.

-

Larger systems, like 4, 6, 8, or even 12+ heads, are common in both traditional and technical embroidery, especially when scaling up production for commercial or industrial purposes.

Multi-head machines maintain precise synchronization, ensuring uniform quality across all embroidered products. This is critical in technical applications where exact fiber placement, electrical continuity, or aerodynamic performance might depend on stitch-perfect replication across multiple parts.

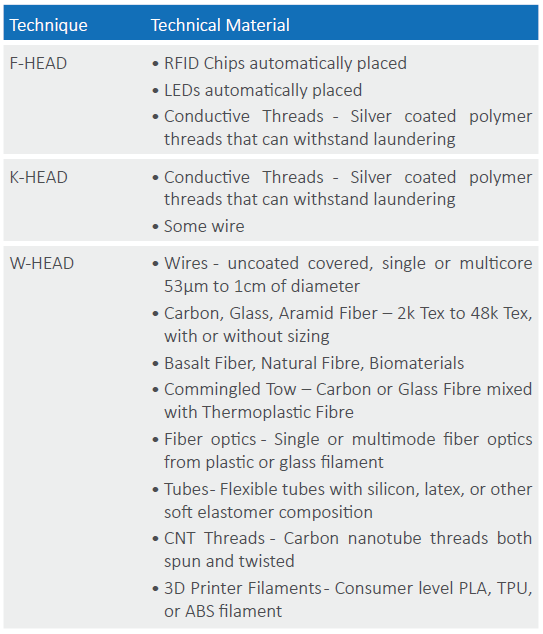

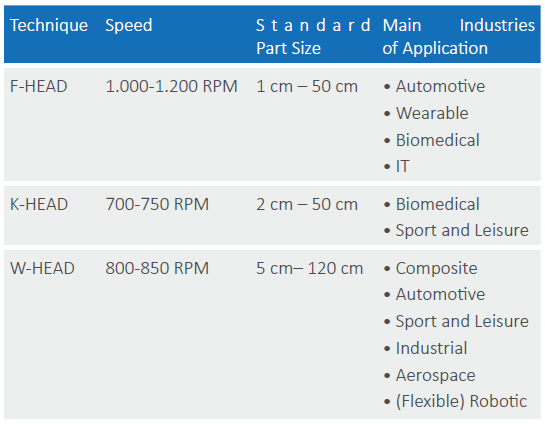

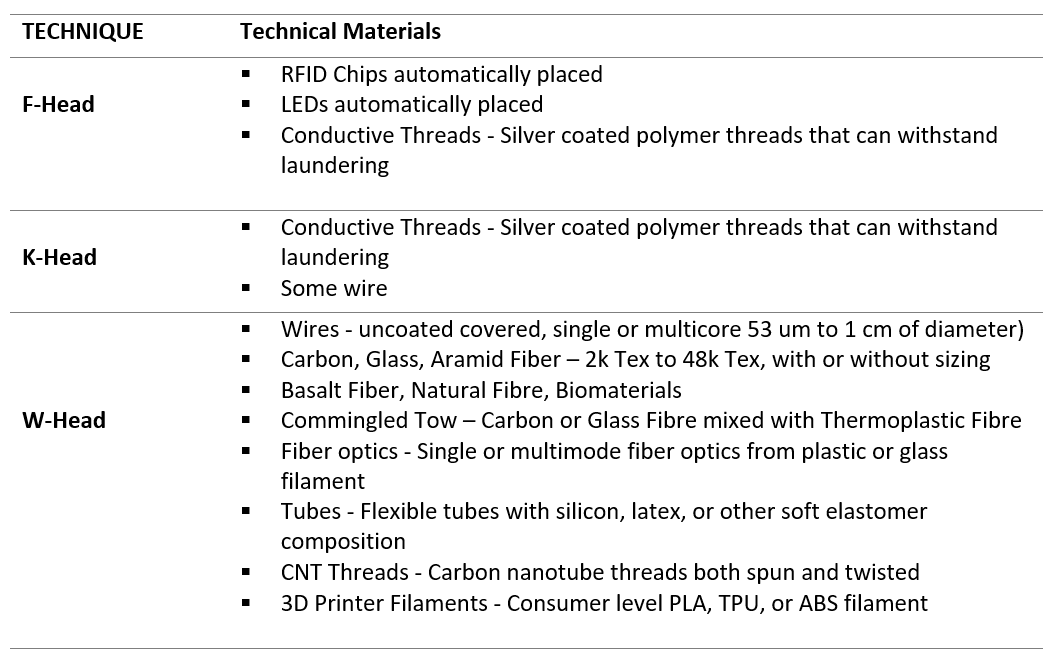

W-Head Embroidery (Tailored Fiber Placement, TFP)

-

Purpose: Used for laying down continuous fibers, such as carbon fiber, fiberglass, aramid (Kevlar®), or specialized yarns.

-

How it works: The W-Head places technical fibers precisely onto a substrate using a zigzag or tailored stitch, allowing exact control over fiber orientation and density.

-

Applications:

-

Aerospace composite reinforcement

-

Automotive lightweight components

-

Sporting goods (bike frames, skis, etc.)

-

Load-bearing structures in architecture and civil engineering

-

Tailored Fiber Placement (TFP) allows structural optimization by orienting fibers exactly where forces will act, reducing material use while increasing strength.

W-Head Embroidery (Cord and Wire Laying)-

Purpose: Used for laying wires, optical fibers, tubing, and thick cords onto textiles.

-

How it works: The W-Head gently places and secures thicker or more delicate materials onto fabric without causing damage. It stitches the material into place with minimal tension or deformation.

-

Applications:

-

Smart textiles (e.g., embedding heating wires or sensors)

-

Fiber optic networks in flexible structures

-

Medical textiles (embedded tubing or flexible circuits)

-

Flexible and wearable electronics

-

The W-Head's gentle laying mechanism is critical when dealing with fragile or performance-critical materials that traditional sewing heads would break or distort.

K-Head Embroidery (Moss and Chain Stitching)

-

Purpose: Used for creating chenille embroidery moss and chain stitches

-

How it works: The K-head uses a single hooked needle to pull a loop of thread from the bottom of the machine to the top, creating a textured surface. By timing, the loop can be stand alone (forest mode or moss mode) or looped through itself creating a chain stitch.

-

Applications:

-

Smart textiles (textile electrodes)

-

Varsity jackets

-

Insulation

-

Fixation of thick threads

-

The K-Head's stitching mechanism requires no rotary hook (unique compared to other stitch types). This means there is no bobbin. For that reason, the K head can stitch longer without an operator replacing bobbins. Additionally, since the thread is a single continuous thread, there are unique mechanical and electrical applications.

F-Head Embroidery (Flatbed Embroidery and Multi-Material Stitching)-

Purpose: Used for traditional embroidery and functional stitching with finer threads or decorative/technical yarns.

-

How it works: The F-Head operates more like a high-precision flatbed sewing machine, offering high-speed stitching with complex patterning capabilities.

-

Applications:

-

Logo embroidery and branding

-

Conductive thread stitching, circuit board stitching

-

Insulation (electrical) layer stitching

-

Fabric reinforcement and assembly

-

In technical embroidery, F-Heads are often used alongside W- or K-Heads to add secondary functions—like stitching around technical fibers for durability or stitching an additional layer over functional materials.

Combining Different Head Types for Maximum Flexibility

A major advantage of ZSK’s technical embroidery platforms is their modular design, allowing multiple head types to be combined on a single machine. For example, a machine might feature a W-Head for laying carbon fiber and an F-Head for securing it with an outer stitch layer—all in one production pass.

This flexibility means you can custom tailor your manufacturing setup to the specific requirements of your application, whether you're building lightweight composite panels, smart wearable devices, or next-generation sensor fabrics.

Why it Matters

Choosing the right combination of heads isn’t just about stitching—it's about unlocking new performance, efficiency, and innovation possibilities:

✅ Precision placement of complex functional materials

✅ Ability to scale to high-throughput production

✅ Integration of multiple material types in a single manufacturing pass

✅ Reduction of material waste through smart design and tailored reinforcementAt the ZSK Research and Training Center in Seattle, we're ready to help you design, configure, and launch the embroidery solutions that will power your next-generation products.

Technical embroidery isn’t just stitching—it’s engineering. And the right embroidery heads are where it all begins.

-