The Pantograph: The Driving Force Behind Precision Embroidery

Section outline

-

The Pantograph: The Driving Force Behind Precision Embroidery

In any modern embroidery machine—whether traditional or technical—the pantograph plays a critical and often underappreciated role. It is the mechanical system that moves the embroidery frame in the X (left/right) and Y (forward/backward) directions, allowing intricate designs to be stitched or technical materials to be precisely placed across the surface of the backing fabric.

The pantograph ensures that the material moves beneath the stationary needle, rather than trying to move the needle itself across the work area. This strategy, born from centuries of embroidery tradition and refined by modern robotics and CNC motion control, is the key to achieving high-speed, highly accurate embroidery.

A Quick Look Back: The History of Embroidery and Machine EvolutionEmbroidery as an art form dates back thousands of years, with ancient examples found from China, Egypt, and India. Originally, embroidery was performed entirely by hand—a time-consuming and painstaking process where artisans moved the needle through a stationary fabric surface.

The modern era of embroidery machines began in the early 19th century with manually operated chain stitch machines. By the late 1800s and early 1900s, machines began to evolve, particularly in Europe (notably in Germany and Switzerland), where innovators developed mechanical solutions to automate parts of the process.

The pantograph system was introduced as a breakthrough innovation, allowing operators to guide a needle across a large work area using a mechanical tracing arm. Early pantograph embroidery machines were manually operated with large templates.

Fast forward to today: modern technical embroidery machines use computer numerical control (CNC) to move the pantograph automatically and with extreme precision, based on a digital design file. No more tracing by hand—every stitch or material placement is driven by sophisticated software and high-speed electronics.

What Exactly is the Pantograph?The pantograph is the mechanized XY table that holds the embroidery frame (which in turn holds your fabric or substrate). It physically moves the entire frame precisely according to the design path programmed into the machine's control system.

Key Functions of the Pantograph:

-

X-Axis Movement (left and right)

-

Y-Axis Movement (forward and backward)

-

Holding and tensioning the embroidery frame securely during motion

-

Coordinating with the embroidery head to ensure perfect stitch placement

Unlike what some might assume, the needles themselves do not "draw" across the fabric. Instead, the needle moves up and down vertically while the pantograph moves the material horizontally under the needle, effectively "painting" the design with thread, wire, fiber, or other technical materials.

How Does the Pantograph Move? (Motor Systems Explained)Modern pantographs are driven by high-precision motors, which are typically either:

-

Servo motors (for high-speed, high-accuracy industrial embroidery machines)

-

Stepper motors (in smaller or more cost-conscious machines)

Servo Motors:

-

Offer continuous feedback on position and speed, meaning the controller knows exactly where the frame is at all times.

-

Allow for dynamic speed adjustments mid-design, for example slowing down for complex corners and speeding up on straight paths.

-

Provide higher accuracy and smoother motion, critical for technical embroidery applications like fiber placement, heating wire layout, or flexible circuits.

Stepper Motors:

-

Move in fixed steps without feedback.

-

Are simpler and less expensive but slightly less precise at very high speeds or with highly complex designs.

In advanced technical embroidery systems like those from ZSK, industrial-grade servo motors are standard, enabling frame movements that are smooth, rapid, and synchronized perfectly with the needle cycles.

Why the Pantograph is Essential for Technical EmbroideryAcross all three major technical embroidery methods—W-Head (Tailored Fiber Placement), K-Head (Cord and Wire Laying), and F-Head (Flatbed Functional Stitching)—the pantograph remains the common foundation:

✅ In W-Head embroidery, the pantograph guides the base material while fibers are precisely stitched down along pre-programmed trajectories.

✅ In K-Head embroidery, it ensures that delicate wires, cords, or tubes are gently and accurately placed without stretching or damaging them.

✅ In F-Head embroidery, it allows detailed, complex stitching patterns to be built rapidly, layer by layer, even when multiple material types are involved.Without a reliable, high-performance pantograph, achieving precision technical embroidery would be impossible. It acts as the "invisible hand" steering the entire embroidery process from underneath.

A Note on the Naming of PantographsThe term "pantograph" originally comes from the Greek roots:

-

"panto-" meaning "all" or "every"

-

"-graph" meaning "writing" or "drawing"

In early machines, the pantograph was literally a mechanical arm that could copy drawings at different scales—thus, the same name came to be used in embroidery machinery, where designs are "drawn" onto fabric by moving the material under a stationary needle.

Today, in technical embroidery, the term honors that tradition—while the function has become far more advanced, involving CNC programs, CAD-generated designs, and real-time motion control.

In SummaryThe pantograph is the soul of motion in embroidery machines.

It moves the world underneath the needle, enabling high-speed, high-precision, and highly creative technical embroidery that is revolutionizing industries from aerospace to smart textiles.At the ZSK Academy, we train innovators not only on operating embroidery machines—but on understanding the fundamentals of pantograph design and control, so they can truly master the new frontier of textile engineering.

Move the material. Change the world.

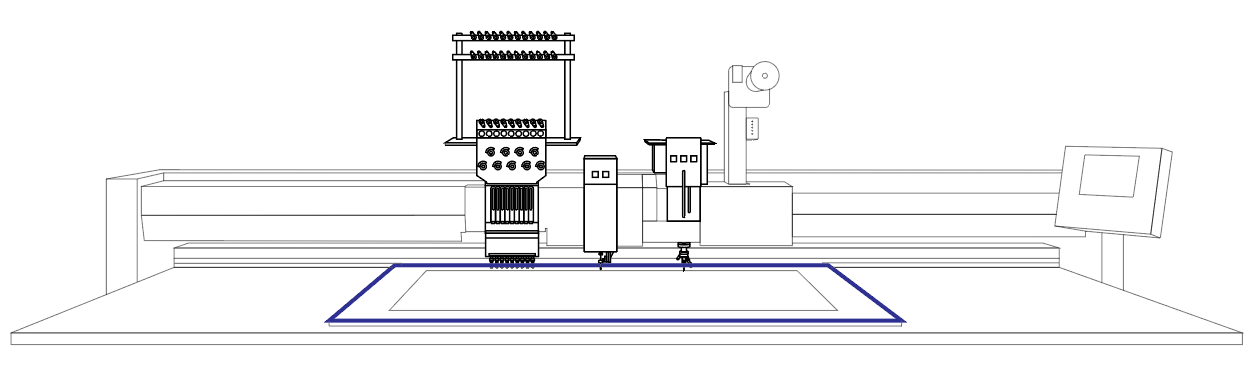

The Pantograph holds the frame (in blue) which allows for X and Y movement on the embroidery table.

-