Introduction to Smart Textiles

Section outline

-

In recent years, a class of technical textiles known as e-textiles has emerged, revolutionizing the way we perceive and use traditional fabrics. E-textiles, or electronic textiles, integrate advanced electronics and their electrical properties into fabrics, giving birth to a new breed of self-aware materials. Equipped with internal sensing capabilities, these materials have the ability to adapt to various changing environments. This opens doors to data collection opportunities that were previously uneconomical or even impossible. For example, smart garments can monitor vital signs in medical settings or track performance metrics in sports.

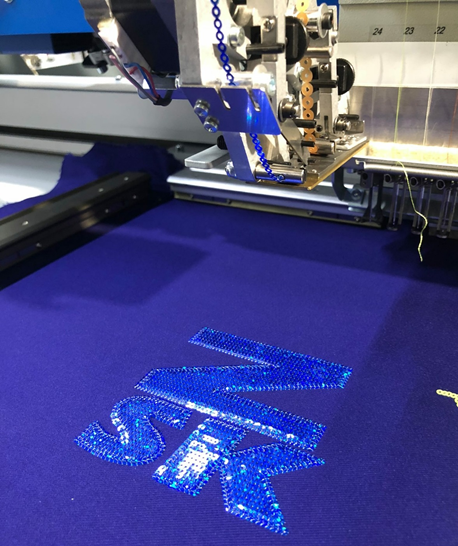

Technical embroidery plays a vital role in the development and advancement of e-textiles. Thanks to its high maneuverability, quick adaptability to intricate designs, and proven scalability, embroidered systems are increasingly being sought after to create prototypes and solutions for the rapidly expanding e-textiles market. Technical embroidery uses a combination of specific tools such as the thread take-up lever, rotary hook, and bobbin case to create precise and complex designs on textiles. The thread take-up lever ensures smooth thread feeding, while the rotary hook is essential for the lockstitch formation, and the bobbin case holds the bobbin thread in place, all crucial for achieving high-quality embroidered circuits.

Technical embroidery opens up new possibilities in the design and manufacture of e-textiles. It allows traditional circuit boards to be mechanically mounted onto fabrics, while simultaneously creating conductive textile connections. Aspects of traditional circuit board design such as creating conductive traces can also be incorporated using technical embroidery. This is achieved by embroidering with conductive threads, which can create complex circuit patterns directly onto the fabric. Sensors can be integrated exactly where they are needed in an automated process, enhancing the functionality and user-friendliness of the final product. Conductive threads, often made from materials like silver-coated fibers or stainless steel, are key to ensuring reliable electrical pathways within the fabric.

Moreover, with the continuous miniaturization of electrical components, there has been a resurgence of interest in mounting components onto embroidered sequins, thereby expanding design possibilities. For instance, LEDs and microcontrollers can be mounted onto sequins and then embroidered onto the fabric to create interactive and visually appealing e-textiles. This not only enhances the aesthetic appeal but also allows for advanced features such as dynamic lighting and responsive feedback in garments.

Common Mistakes:

- Not considering the washability and durability of e-textiles: It's crucial to ensure that the electronic components and conductive threads used can withstand washing and regular wear and tear. Use of waterproof coatings and encapsulation methods can help protect sensitive components.

- Overlooking the comfort and flexibility of the final product: E-textiles should be comfortable to wear and flexible to accommodate movement. Careful selection of base fabrics and placement of electronic elements can improve garment comfort.

- Failing to properly insulate conductive threads: This can lead to short circuits and malfunctions. Insulating layers or coatings can be applied to prevent unintended electrical contact.

Learn More:

- ASTM Textile Standards

- ISO Textile Standards

- Research Paper: Technical Embroidery for Smart Textiles: Fabrication Processes and Applications

-

Technical Embroidery: An Introduction

Overview of Technical Embroidery

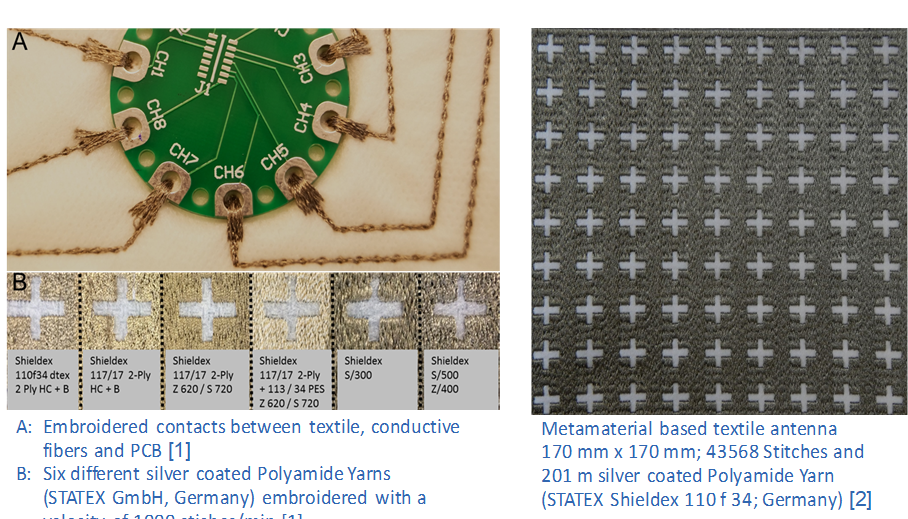

Technical embroidery refers to the integration of traditional embroidery techniques with modern digital technologies. This innovative practice has revolutionized the textile industry, particularly in the field of technical textiles and e-textiles. One of the most direct uses of technical embroidery is to quickly attach and stitch traditional printed circuit boards (PCBs) into fabric carriers.

Stitching PCBs directly into the structure of the textile, using components such as the thread take-up lever, rotary hook, and bobbin case, reduces mechanical strains on the connectors while allowing the control and processing electronics to be physically closer to their supporting electronics. The thread take-up lever plays a crucial role in maintaining thread tension, while the rotary hook is essential for creating the lockstitch by catching the top thread. The bobbin case holds the bobbin, ensuring smooth thread delivery. This technique can have a range of benefits such as increased signal-to-noise ratio, decreased mechanical fatigue-based failure, and reduced need for additional connectors. These advantages are particularly significant in applications where reliability and durability are critical, such as in medical devices or aerospace textiles.

The Electronics Packaging Standpoint

If looked at from an electronics packaging standpoint, fabrics offer a new host of materials that not only house the electronics but also provide functional advantages over traditional materials and processes. This is largely due to the inherent flexibility, breathability, and lightweight nature of textiles, which allows for the creation of more comfortable and wearable electronic devices. Moreover, textiles can be engineered to provide additional functionalities such as moisture-wicking, antibacterial properties, and thermal regulation, making them ideal for wearable technology applications.

Embroidery of Full Board Systems

Technical embroidery isn't limited to stitching individual components; full board systems can be embroidered with a wide variety of different off-the-shelf boards. This opens up a new realm of possibilities for the design and manufacture of electronic textiles, from smart clothing to wearable medical devices. By integrating sensors, actuators, and microcontrollers directly into the fabric, designers can create garments that monitor health metrics, provide feedback, or interact with the environment. This capability is particularly valuable in fields such as sports performance, health monitoring, and safety apparel.

Learn More

For further reading on the topics covered in this module, consider the following resources:

- Technical Embroidery for Smart Textiles - A research paper on ResearchGate

- ASTM Textile Standards - Standards from ASTM International

- ISO Standards Catalogue - Standards from the International Organization for Standardization

Note: Keep in mind that mastering industrial machine embroidery requires a blend of theoretical knowledge and practical skills. Always practice under the guidance of an experienced professional. Additionally, understanding the maintenance and troubleshooting of embroidery machines, including the proper handling of the thread take-up lever, rotary hook, and bobbin case, is essential for achieving high-quality results.

-

Technical Embroidery in E-Textiles Manufacturing

Technical embroidery, a modernized form of traditional embroidery, has emerged as a significant player in the e-textiles manufacturing industry. One of its key advantages lies in its ability to automatically embroider electrical connections onto a host board using various conductive threads. This innovative process paves the way for quick and efficient connection of potentially hundreds of electrical connections from a board to their fabric-hosted sensors.

Conductive threads, also known as e-threads, are threads coated or infused with metals or other conductive materials, allowing them to carry an electrical current. They come in a variety of thicknesses and strengths, enabling designers to choose the right thread for their specific application. Conductive threads are typically made from materials such as silver, copper, or stainless steel, which are known for their excellent conductivity and durability. The selection of thread is crucial, as it affects the electrical performance and the mechanical integrity of the textile.

Common mistakes in this process include misalignment of connections due to improper registration of the board, incorrect thread tension, and use of inappropriate conductive thread type. Proper knowledge of the embroidery machine's functionalities, such as the thread take-up lever, rotary hook, and bobbin case, is also crucial for successful operation. The thread take-up lever ensures smooth thread flow during stitching, while the rotary hook catches the thread to form a stitch. The bobbin case holds the lower thread and must be correctly tensioned to avoid stitch defects.

Registration of the Board and Stitching

By carefully registering the board during its embroidery to the host fabric, the electrical connection points on the board are also registered for stitching. This precise process can allow for a single stitched board to merge data from many sensor types into a single output, enhancing the efficiency and versatility of e-textiles. This technique is especially valuable in the production of smart textiles and wearables, where multiple sensors are often integrated into a single piece of fabric. Accurate registration is critical to ensure that the conductive pathways align perfectly with the components they are meant to connect.

The role of the embroidery machine in this process cannot be overstated. The machine's precision and speed, combined with the correct use of its components such as the needle bar, presser foot, and rotary hook, are vital for achieving accurate registration and stitching. The needle bar moves the needle up and down through the fabric, while the presser foot holds the fabric in place, allowing for consistent stitching. The rotary hook's motion is synchronized with the needle to form precise and reliable stitches.

Learn More

For those who wish to delve deeper into the subject, the following resources provide more detailed information:

-

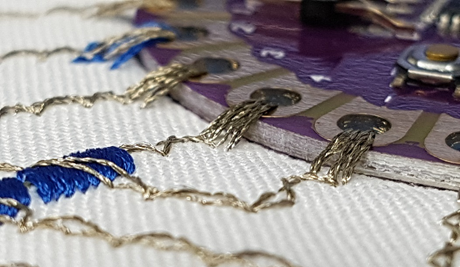

Introduction to Conductive Threads in Embroidery

Embroidery has evolved from a craft to a sophisticated technology where it is possible to integrate electronic components into textile substrates. This transformation is largely due to the development of conductive threads, which are essential for creating e-textiles and smart garments. Conductive threads are typically made from materials such as silver, stainless steel, or copper, which are known for their excellent conductivity. By using techniques such as tailored wire placement, highly conductive materials can be placed into the fabric's structure to create low resistance traces. These traces function similarly to traditional circuit boards, allowing for the seamless integration of electronic circuits into textiles.

In this context, wire sizes ranging from AWG 10 to AWG 40 have been successfully used. The American Wire Gauge (AWG) is a standard method used in the United States and other countries to denote the diameter of electrically conducting wires. The higher the AWG number, the thinner the wire. Thus, AWG 10 wire is thicker than AWG 40 wire. Thicker wires (lower AWG numbers) are typically used for applications requiring higher current capacity, while thinner wires (higher AWG numbers) are suited for more intricate designs where flexibility and minimal bulk are crucial.

Wire Coatings and Customized Wires

Wire coatings play a crucial role in the integration of wires with textiles. Coatings such as enamel, polyurethane, or PVC are used to insulate the conductive core, ensuring that the embroidery process does not compromise the wire's functionality. These coatings prevent short circuits and protect the wire from environmental factors like moisture and abrasion, which could degrade its performance over time. The choice of coating material can also affect the wire's flexibility, making it an important consideration in design.

Furthermore, the embroidery process allows for the use of customized wires such as multicore and multifilament wires. These wires consist of multiple conductive strands bundled together, which can carry several signals through a single conductive path, thereby enhancing the functionality of the e-textile. With current technology, up to 32 signals in a single multicore line can be run, with the capability of going much higher. This capability is particularly valuable in complex e-textile applications where multiple sensors or actuators need to be integrated into a single garment.

Applications and Future Developments

The integration of conductive threads and wires into textiles has paved the way for the development of smart textiles and wearables. These innovative products have applications in various fields such as healthcare, where they can be used for continuous monitoring of vital signs; sports, where they can track performance metrics; military, where they can offer enhanced communication capabilities; and fashion, where they enable interactive and dynamic designs. Future developments in this area are likely to increase the functionality of these products and reduce their cost, making them more accessible for widespread adoption. Researchers are also exploring the use of nanotechnology and advanced materials to further enhance the properties of conductive threads, such as improving their conductivity, durability, and comfort.

Learn More

- ASTM Textile Standards - A comprehensive resource for standards in textile materials and testing.

- ISO Standards for Textiles - International standards for textiles, ensuring quality and safety in textile production.

- Research Paper: Embroidery and related manufacturing techniques for wearable antennas: A review - A detailed examination of how embroidery techniques are used to create antennas for wearable technology.

-

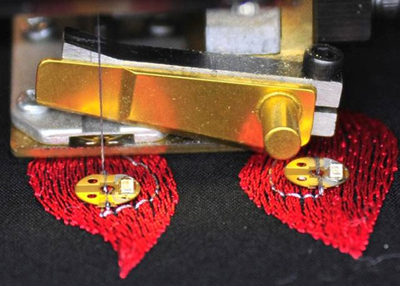

Traditional sensors such as temperature sensors can be embroidered into a textile by using two primary methods: embroidering the host circuit board into the textile, or integrating the sensor into a fiber carrier. The first method involves using a specialized embroidery machine, where a pre-designed circuit board is stitched directly onto the fabric. This approach, while straightforward and quick, often results in a rigid and inflexible textile. To achieve this, the machine uses a digitized design, guiding the needle and thread to secure the circuit board onto the fabric. It's crucial to ensure that the thread take-up lever and rotary hook are properly synchronized to avoid thread breakage and maintain precise stitch formation.

The second method, embroidering sensors within a fiber carrier, is a more complex process. Here, the sensors are embedded within the fibers themselves before the embroidery process begins. This technique can lead to a more elegant and compliant solution, creating a textile that maintains its flexibility and comfort while carrying the functionality of the sensors. It's important to note that this method requires careful consideration of the thread tension, stitch density, and design complexity to ensure the integrity and functionality of the sensor. For example, adjusting the bobbin case tension is critical to prevent puckering and to maintain the sensor's connectivity throughout the textile. Additionally, selecting the appropriate type of embroidery thread, such as conductive yarns, is essential for maintaining the electrical properties required for sensor functionality.

However, the field of e-textiles is constantly evolving, and more form-fitting and haptic-sensitive textile-based sensors are being explored. These sensors leverage the properties of conductive fibers themselves such as large surface areas, variable resistivity, and geometric conformability. As a result, innovative solutions such as textile electrodes, stretch sensors, and sweat sensors can be reliably created. These sensors can be used in a variety of applications, ranging from wearable technology and smart clothing to healthcare and athletic performance monitoring. For instance, stretch sensors embedded in athletic wear can provide real-time feedback on muscle movements, while sweat sensors can monitor hydration levels and electrolyte balance during physical activities.

Learn More

For those interested in diving deeper into the world of e-textiles and embroidered sensors, the following resources provide excellent starting points:

- ASTM: Embroidered Conductive Fibers for Sensor Integration

- ISO: Smart textiles - Definitions, categorization, applications, and standardization needs

- ScienceDirect: An overview of smart technologies for clothing design and engineering

These resources offer comprehensive insights into the technical aspects of e-textiles, including the process of integrating sensors into fiber carriers, the challenges of creating form-fitting and haptic-sensitive sensors, and the future trends in this exciting field. They cover the historical evolution of smart textiles, the current state-of-the-art technologies, and future possibilities such as self-healing materials and energy-harvesting fabrics, which could revolutionize how we interact with textiles in everyday life.

-

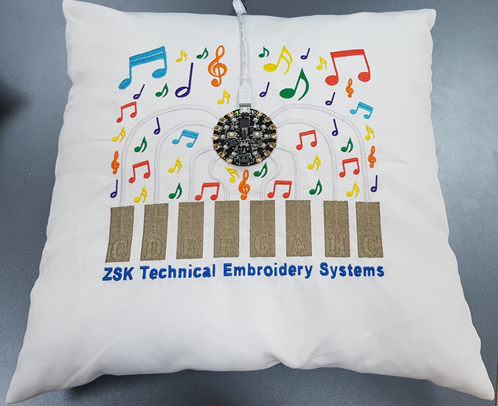

One innovative method of functionalizing fabrics in the field of technical textiles is the incorporation of embroidered LED sequins. This process involves mounting the necessary electronics onto a traditional sequin carrier and using an industrial embroidery machine to robotically sew the LED sequins into the fabric during its creation. This method offers significant advantages over other e-textile processes, as it eliminates the need for post-process soldering or the use of additional conductive epoxies.

Embroidered LED sequins exemplify the integration of electronics within textile structures, creating smart textiles that can react to environmental stimuli or user interaction. This integration is achieved through the precise control of the embroidery machine, which seamlessly incorporates electronic components into the fabric. By using conductive threads, the machine establishes electrical connections between the LEDs and the power source, often a small battery pack discretely housed within the garment.

Historically, the use of LEDs in textiles was limited due to the need for bulky wiring and separate power sources. However, with the advent of miniaturized electronics and advanced embroidery techniques, it is now possible to integrate LED sequins directly into the fabric structure, creating luminous textiles with various applications ranging from fashion and design to safety and communication.

The evolution of this technology can be traced back to early experiments with electroluminescent wires and fiber optics, which, while innovative, lacked the flexibility and comfort required for wearable applications. Today, embroidered LEDs offer a solution that is both aesthetically pleasing and functionally robust, opening new possibilities for interactive clothing, illuminated safety gear, and dynamic display textiles.

Figure 1: Embroidered LED sequin

Figure 2: LED sequin mounted on a traditional carrier

Figure 3: Robotic sewing of LED sequins into fabric

In this process, the embroidery machine serves as a hybrid between traditional pick and place machines, which select a component sequin off of a reel, and a sequin machine, as it stitches the component into the fabric’s structure. This represents a significant advancement in the field of e-textiles, combining the precision of automated machinery with the versatility of traditional embroidery techniques.

It's important to note that the quality of the final product is highly dependent on the machine settings, especially the thread tension, thread take-up lever, rotary hook, and bobbin case settings. These must be finely tuned to ensure consistent stitching and proper placement of the LED sequins.

The thread take-up lever is crucial as it ensures that the thread is correctly fed through the needle, preventing slack that could lead to uneven stitching or thread breakage. Similarly, the rotary hook, which captures the needle thread to form a stitch, must be precisely aligned to avoid skipped stitches. The bobbin case, holding the lower thread, must maintain consistent tension to ensure balanced stitching with the top thread.

Common mistakes include incorrect threading, improper tension settings, and misalignment of the LED components, all of which can lead to functional failures or aesthetic defects. Therefore, regular machine maintenance and calibration are essential for optimal performance.

Figure 4: Industrial embroidery machine

Learn More:

- ASTM Textile Standards

- ISO Standards

- Research Paper: Embroidery and related manufacturing techniques for wearable antennas

- Research Paper: Industrial embroidery for technical textiles

-

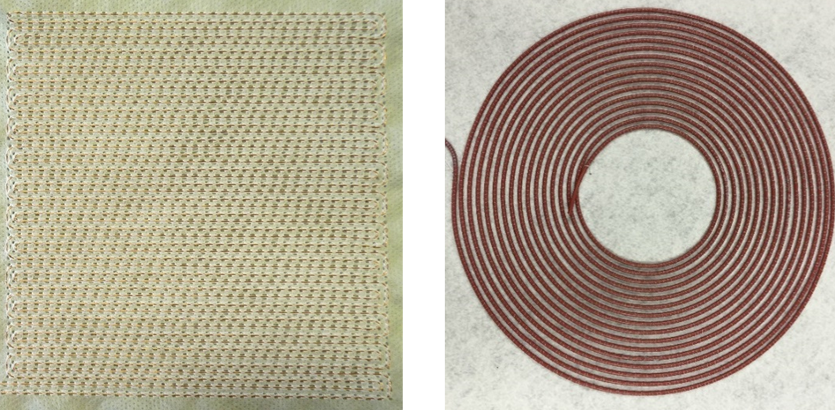

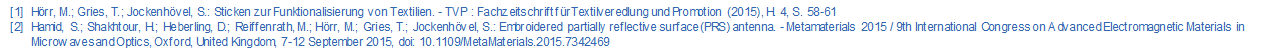

Technical embroidery, an advanced application of textiles, has been making significant strides in radio frequency engineering. This is made possible through the creation of geometrically tunable antennas. These antennas, crafted using embroidery techniques, can adapt their shape, providing a dynamic approach to signal transmission and reception. The malleability of textiles, which can dramatically alter their shape when stored versus when worn, offers limitless possibilities for the design of these antennas.

The embroidery process, which involves the use of a thread take-up lever, rotary hook, and bobbin case among other tools, allows for the creation of intricate and diverse antenna shapes. The thread take-up lever ensures consistent tension and smooth feeding of the thread, while the rotary hook captures the upper thread to form a lockstitch, and the bobbin case holds the lower thread in place. This precise coordination is crucial in maintaining the integrity and functionality of the embroidered pattern. This is a significant break from traditional hard antennas which are typically limited in their design possibilities.

Figure 1: A depiction of the technical embroidery process, showcasing the creation of a geometrically tunable antenna. Notice the intricate use of conductive threads that form the basis of the antenna structure.

Figure 2: A textile antenna created using technical embroidery techniques. The design demonstrates the flexibility of textile substrates in accommodating complex antenna configurations.

Figure 3: An example of a textile antenna in use, showcasing its unique directional properties. The adaptability of these antennas allows them to be integrated seamlessly into garments, enhancing their practical applications.

These designed textile antennas exhibit unique directional properties not found in traditional hard antennas. As our world becomes more interconnected and wireless, the development and application of textile antennas are an open and exciting area of research. They have the potential to revolutionize wearable technology, smart textiles, and more. Textile antennas can be integrated into clothing, providing a discreet and flexible solution for communication systems, health monitoring, and even environmental sensing.

However, the process of creating these antennas is not without its challenges. Understanding the materials and the properties of the thread used, such as conductivity and durability, is crucial. Managing the tension during the embroidery process is essential to avoid distortions in the antenna pattern. Ensuring the correct alignment of the design is vital for the functionality of the antenna, as misalignment can lead to signal loss or interference. Additionally, it's important to understand how the final textile product will be used and the environment it will be exposed to, as these factors can influence the effectiveness of the textile antenna. For example, moisture and mechanical stress can affect the performance of conductive threads.

Learn More

For further reading and research on the application of technical embroidery in the creation of textile antennas, refer to the following resources:

- Research Paper: Embroidery of Electromagnetic Radiators onto Textile Substrates for RF Engineering Applications

- ASTM Textile Standards

- ISO Standards for Textiles

- The Textile Institute

-

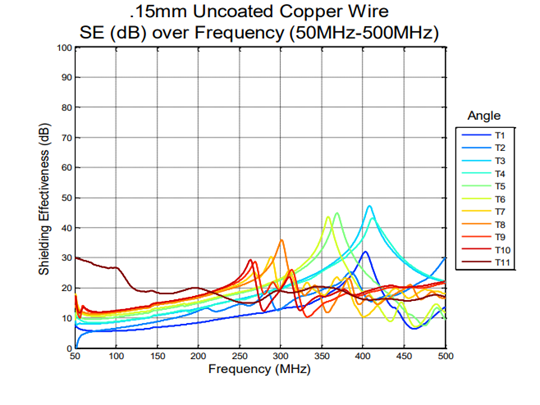

Embroidery, a technique traditionally known for its decorative applications, has found a critical role in the world of technical textiles, specifically in the creation of intricate electromagnetic interference (EMI) shielding. EMI shielding is a crucial aspect of electronic device design, preventing unwanted electromagnetic signals from causing disruption or damage. The embroidery method allows for frequency-selective shielding to be produced quickly and accurately. This is achieved by changing the patterns of the embroidered conductive traces, where different signals can be blocked or allowed to pass through the technical textile. In an era of increasing digital connectivity, this control of signal propagation becomes increasingly valuable.

This is an example of a two-layer stack-up of wire creating a box-type electromagnetic shield. The complex pattern intricately embroidered allows for specific frequencies to be selectively blocked. The use of a bobbin case and rotary hook in the embroidery machine ensures precise placement of conductive threads, which is critical for achieving the desired shielding effectiveness.

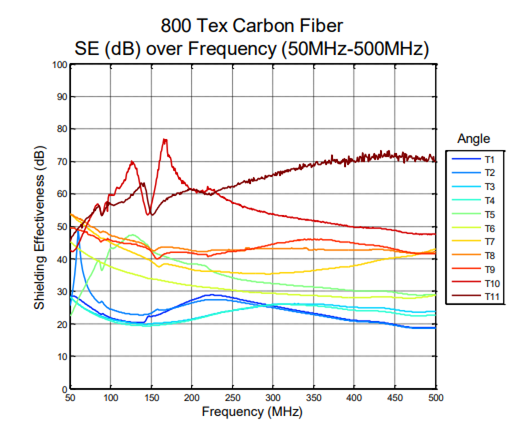

This graph displays the areas of frequency-selective shielding effectiveness. The peaks represent the frequencies where the shielding is most effective. Adjusting the tension and thread take-up lever on the embroidery machine can influence these peaks by altering the density and pattern of the conductive traces.

Apart from metallic wires, carbon fiber can also be used as a shielding material due to its orthotropic electrical properties, which allow it to conduct electricity in certain directions better than others. This directional conductivity is key in designing textiles that need to manage electromagnetic waves effectively across different axes.

The shielding effectiveness of embroidered carbon fiber is similar to that of a copper shield. However, one significant advantage of using carbon fiber is the higher control over its thickness, offering more flexibility in design and application. This flexibility is particularly beneficial in applications like wearable technology, where comfort and adaptability are as important as functionality.

For a deeper understanding of this topic, refer to the following study:

Anderson, T. (2013). Fabrication and characterization of carbon fiber composite-based electromagnetic interference shielding for simultaneous PET/MRI. Master’s Thesis, RWTH Aachen University, Aachen, Germany. This thesis explores the innovative use of carbon fiber in creating effective EMI shields, comparing its performance to traditional materials like copper and examining its implications for advanced textile applications.

Learn More:

- ASTM Textile Standards - Explore comprehensive guidelines and standard practices for textile materials, essential for ensuring quality and consistency in industrial applications.

- ISO Standards for Textiles - Delve into international standards that govern the testing methods and performance criteria for textiles, including those used in technical applications.

- Research Paper on EMI Shielding Effectiveness of Textile Materials - A detailed examination of various textile materials and their effectiveness in EMI shielding, providing insights into material selection and design strategies.

-

One of the key considerations when evaluating an e-textile prototype is its scalability. This refers to the ability to increase production volume quickly and cost-effectively. In the context of e-textiles, small batch manufacturing solutions can produce less than 500 parts per day. This is achievable depending on the size and complexity of the design, using a single head roll2roll machine.

With this type of machine, a roll of fabric is inserted into the front of the machine. The fabric is then automatically pulled through the machine, where it undergoes the embroidery process. This process involves the precise movement of the fabric under the needle, orchestrated by components such as the thread take-up lever and rotary hook, which ensure consistent stitching. After embroidering, the fabric is fed to a feeder roll located at the back of the machine for collection. The single head roll2roll machine is a marvel of modern textile technology, seamlessly integrating traditional embroidery techniques with automated processing. Such machines are crucial for applications requiring high precision and repeatability, such as in the production of sensors and conductive pathways in smart textiles.

JGW Single Head Roll2Roll Machine for Small Batch Manufacturing

Embroidery, being a time-honored textile process, comes with a wide array of production machine configurations. This robustness significantly reduces the risk associated with scaling up production, especially when compared to newer, less-established e-textile processes. Fully automatic and scalable roll to roll solutions exist and are heavily utilized in industries such as car seat heating, where conductive threads are embroidered to create heating elements, and other technical textile sectors like medical textiles for monitoring health parameters.

Interestingly, many traditional embroidery companies can adapt their existing equipment setup to transition their production from traditional embroidery to technical e-textiles embroidery. This adaptability is facilitated by the modular design of embroidery machines, which often allows for the integration of additional components such as sensors and actuators needed for e-textile applications. This is a testament to the flexibility and adaptability of embroidery technology in the face of evolving textile needs. For example, the bobbin case, a critical component in maintaining thread tension, can be adjusted to accommodate conductive threads, which may have different properties compared to standard embroidery threads.

Learn More:

- ASTM Textiles Standards: Learn more about international standards for textiles.

- ISO E-Textiles Standards: Understand the international standards for e-textiles.

- E-textiles: Fabric circuits and commercial sewing machines: A research paper that explores the integration of circuits into fabric using commercial sewing machines.

-

Joining Technologies for Electronic Textiles

Electronic textiles, also known as e-textiles, are fabrics that have been enhanced with digital components such as LEDs, sensors, and other electronic devices. These components are joined to the textiles using a variety of methods, including weaving, knitting, and embroidery. Each method offers unique advantages and limitations. For instance, weaving and knitting allow the integration of electronic components during the fabric formation, providing seamless integration and enhanced durability. Embroidery, on the other hand, enables precision placement of electronic components on pre-existing fabrics, allowing for retrofitting capabilities. This section will explore these joining technologies in depth, focusing on their advantages, limitations, and practical applications in areas such as wearable technology, health monitoring, and interactive textiles.

Innovations in conductive yarns and threads, such as copper-plated fibers and silver-coated threads, have expanded the possibilities for creating reliable electrical pathways within textiles. Understanding the properties of these materials, including conductivity, flexibility, and tensile strength, is crucial for successful e-textile integration.

https://www.researchgate.net/publication/283232616_Joining_technologies_for_electronic_textiles

Technical Embroidery for Smart Textiles: Review

Technical embroidery is a powerful tool in the production of smart textiles. Using specialized embroidery machines equipped with capabilities such as the thread take-up lever and rotary hook systems, conductive threads can be embroidered directly onto fabric, creating intricate circuits. This approach has significant advantages over traditional printed circuits, including flexibility, durability, and the ability to incorporate into existing textile manufacturing processes.

One of the key benefits of technical embroidery is its ability to produce complex geometries and multilayered structures that can support a variety of electronic components. Common applications include heating elements, sensors, and antennas. The choice of conductive thread is critical, with options ranging from stainless steel to silver-coated polymers, each offering different levels of conductivity and wear resistance.

This section will provide a comprehensive review of technical embroidery techniques, materials, and applications, highlighting case studies where embroidered circuits have been successfully implemented in smart garments and protective gear.

https://www.researchgate.net/publication/277631766_Technical_Embroidery_for_Smart_Textiles_Review

Smart Protective Clothing for Law Enforcement Personnel

Smart textiles are increasingly being used to enhance the safety and effectiveness of law enforcement personnel. These smart protective clothing items can include features such as integrated body cameras, GPS tracking, biometric monitoring, and even electric shock capabilities for self-defense. The integration of such technologies requires careful consideration of power supply management, data transmission security, and user comfort.

This section will explore the design, manufacture, and practical use of these innovative garments. We will discuss the challenges of integrating rigid electronic components into flexible textiles, the role of modular designs for easy maintenance and upgrades, and the importance of ensuring that these garments meet industry safety standards.

Textiles with Integrated Sleep-Monitoring Sensors

Sleep-monitoring sensors are a promising application of smart textiles in the healthcare industry. By integrating these sensors into bedding or sleepwear, it is possible to continuously monitor a person's sleep patterns without the need for uncomfortable and intrusive equipment. These sensors can track metrics such as heart rate, breathing patterns, and body movement.

This section will discuss the design and manufacture of these sensor-integrated textiles, as well as their potential benefits and challenges. Topics will include the selection of suitable sensor materials, methods for embedding sensors into textiles without compromising comfort, and strategies for data collection and analysis to provide meaningful insights into sleep quality.

https://www.researchgate.net/publication/303416021_Textiles_with_Integrated_Sleep-Monitoring_Sensors

Design and Manufacture of Textile-Based Sensors

Textile-based sensors are a crucial component of many smart textile applications. These sensors can be designed to detect a wide range of physical and environmental factors, including temperature, humidity, pressure, and chemical composition. The design process involves selecting appropriate materials, such as piezoresistive fabrics for pressure sensing or thermochromic inks for temperature detection.

In this section, we will delve into the principles of textile-based sensor design and manufacture, exploring topics such as material selection, sensor integration techniques, and calibration methods. We will also examine case studies showcasing innovative applications, such as pressure-sensitive socks for diabetic foot monitoring and chemical-sensitive gowns for hazardous material detection.

https://www.researchgate.net/publication/282687882_Design_and_manufacture_of_textile-based_sensors

Learn More

For additional resources and further reading, consider the following links:

ASTM Textile Standards - A comprehensive collection of standards that ensure quality and safety in textile production.

ISO Standards for Textiles - International standards that cover a wide range of textile-related topics, including smart textiles.

The Future of Smart Textiles - An insightful article exploring the upcoming trends and innovations in the field of smart textiles.

-

Further Reading & Resources

- ASTM Textile Standards

- ISO Textile Standards

- Research Paper: Technical Embroidery for Smart Textiles: Fabrication Processes and Applications

- Technical Embroidery for Smart Textiles

- ISO Standards Catalogue

- ISO Standards

- Technical Embroidery for Smart Clothing: Review and Prospects

- Conductive Thread Guide

- ASTM Textile Standards

- ISO Standards for Textiles

- Research Paper: Embroidery and related manufacturing techniques for wearable antennas: A review

- ASTM: Embroidered Conductive Fibers for Sensor Integration

- ISO: Smart textiles - Definitions, categorization, applications, and standardization needs

- ScienceDirect: An overview of smart technologies for clothing design and engineering

- Research Paper: Embroidery and related manufacturing techniques for wearable antennas

- Research Paper: Industrial embroidery for technical textiles

- Research Paper: Embroidery of Electromagnetic Radiators onto Textile Substrates for RF Engineering Applications

- The Textile Institute

- ISO Standards for Textiles

- Research Paper on EMI Shielding Effectiveness of Textile Materials

- ISO E-Textiles Standards

- E-textiles: Fabric circuits and commercial sewing machines

- https://www.researchgate.net/publication/283232616_Joining_technologies_for_electronic_textiles

- https://www.researchgate.net/publication/277631766_Technical_Embroidery_for_Smart_Textiles_Review

- https://www.researchgate.net/publication/277631673_Smart_Protective_Clothing_for_Law_Enforcement_Personnel

- https://www.researchgate.net/publication/303416021_Textiles_with_Integrated_Sleep-Monitoring_Sensors

- https://www.researchgate.net/publication/282687882_Design_and_manufacture_of_textile-based_sensors