Embroidering traces

Section outline

-

Introduction to Conductive Threads in Embroidery

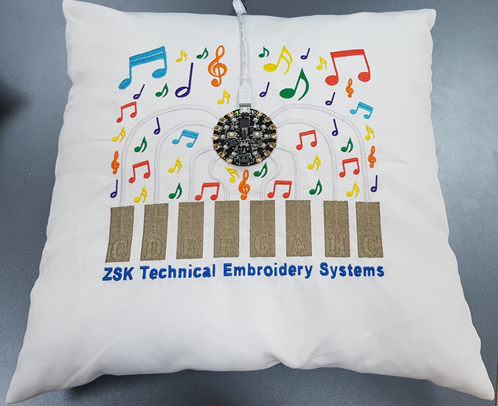

Embroidery has evolved from a craft to a sophisticated technology where it is possible to integrate electronic components into textile substrates. This transformation is largely due to the development of conductive threads, which are essential for creating e-textiles and smart garments. Conductive threads are typically made from materials such as silver, stainless steel, or copper, which are known for their excellent conductivity. By using techniques such as tailored wire placement, highly conductive materials can be placed into the fabric's structure to create low resistance traces. These traces function similarly to traditional circuit boards, allowing for the seamless integration of electronic circuits into textiles.

In this context, wire sizes ranging from AWG 10 to AWG 40 have been successfully used. The American Wire Gauge (AWG) is a standard method used in the United States and other countries to denote the diameter of electrically conducting wires. The higher the AWG number, the thinner the wire. Thus, AWG 10 wire is thicker than AWG 40 wire. Thicker wires (lower AWG numbers) are typically used for applications requiring higher current capacity, while thinner wires (higher AWG numbers) are suited for more intricate designs where flexibility and minimal bulk are crucial.

Wire Coatings and Customized Wires

Wire coatings play a crucial role in the integration of wires with textiles. Coatings such as enamel, polyurethane, or PVC are used to insulate the conductive core, ensuring that the embroidery process does not compromise the wire's functionality. These coatings prevent short circuits and protect the wire from environmental factors like moisture and abrasion, which could degrade its performance over time. The choice of coating material can also affect the wire's flexibility, making it an important consideration in design.

Furthermore, the embroidery process allows for the use of customized wires such as multicore and multifilament wires. These wires consist of multiple conductive strands bundled together, which can carry several signals through a single conductive path, thereby enhancing the functionality of the e-textile. With current technology, up to 32 signals in a single multicore line can be run, with the capability of going much higher. This capability is particularly valuable in complex e-textile applications where multiple sensors or actuators need to be integrated into a single garment.

Applications and Future Developments

The integration of conductive threads and wires into textiles has paved the way for the development of smart textiles and wearables. These innovative products have applications in various fields such as healthcare, where they can be used for continuous monitoring of vital signs; sports, where they can track performance metrics; military, where they can offer enhanced communication capabilities; and fashion, where they enable interactive and dynamic designs. Future developments in this area are likely to increase the functionality of these products and reduce their cost, making them more accessible for widespread adoption. Researchers are also exploring the use of nanotechnology and advanced materials to further enhance the properties of conductive threads, such as improving their conductivity, durability, and comfort.

Learn More

- ASTM Textile Standards - A comprehensive resource for standards in textile materials and testing.

- ISO Standards for Textiles - International standards for textiles, ensuring quality and safety in textile production.

- Research Paper: Embroidery and related manufacturing techniques for wearable antennas: A review - A detailed examination of how embroidery techniques are used to create antennas for wearable technology.