Electromagnetic Shielding

Section outline

-

Embroidery, a technique traditionally known for its decorative applications, has found a critical role in the world of technical textiles, specifically in the creation of intricate electromagnetic interference (EMI) shielding. EMI shielding is a crucial aspect of electronic device design, preventing unwanted electromagnetic signals from causing disruption or damage. The embroidery method allows for frequency-selective shielding to be produced quickly and accurately. This is achieved by changing the patterns of the embroidered conductive traces, where different signals can be blocked or allowed to pass through the technical textile. In an era of increasing digital connectivity, this control of signal propagation becomes increasingly valuable.

This is an example of a two-layer stack-up of wire creating a box-type electromagnetic shield. The complex pattern intricately embroidered allows for specific frequencies to be selectively blocked. The use of a bobbin case and rotary hook in the embroidery machine ensures precise placement of conductive threads, which is critical for achieving the desired shielding effectiveness.

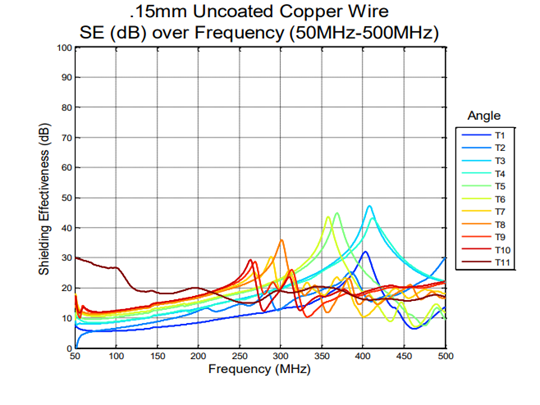

This graph displays the areas of frequency-selective shielding effectiveness. The peaks represent the frequencies where the shielding is most effective. Adjusting the tension and thread take-up lever on the embroidery machine can influence these peaks by altering the density and pattern of the conductive traces.

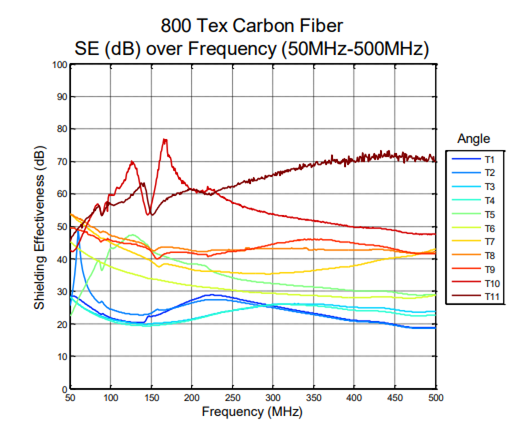

Apart from metallic wires, carbon fiber can also be used as a shielding material due to its orthotropic electrical properties, which allow it to conduct electricity in certain directions better than others. This directional conductivity is key in designing textiles that need to manage electromagnetic waves effectively across different axes.

The shielding effectiveness of embroidered carbon fiber is similar to that of a copper shield. However, one significant advantage of using carbon fiber is the higher control over its thickness, offering more flexibility in design and application. This flexibility is particularly beneficial in applications like wearable technology, where comfort and adaptability are as important as functionality.

For a deeper understanding of this topic, refer to the following study:

Anderson, T. (2013). Fabrication and characterization of carbon fiber composite-based electromagnetic interference shielding for simultaneous PET/MRI. Master’s Thesis, RWTH Aachen University, Aachen, Germany. This thesis explores the innovative use of carbon fiber in creating effective EMI shields, comparing its performance to traditional materials like copper and examining its implications for advanced textile applications.

Learn More:

- ASTM Textile Standards - Explore comprehensive guidelines and standard practices for textile materials, essential for ensuring quality and consistency in industrial applications.

- ISO Standards for Textiles - Delve into international standards that govern the testing methods and performance criteria for textiles, including those used in technical applications.

- Research Paper on EMI Shielding Effectiveness of Textile Materials - A detailed examination of various textile materials and their effectiveness in EMI shielding, providing insights into material selection and design strategies.