Embroidered LED sequins

Section outline

-

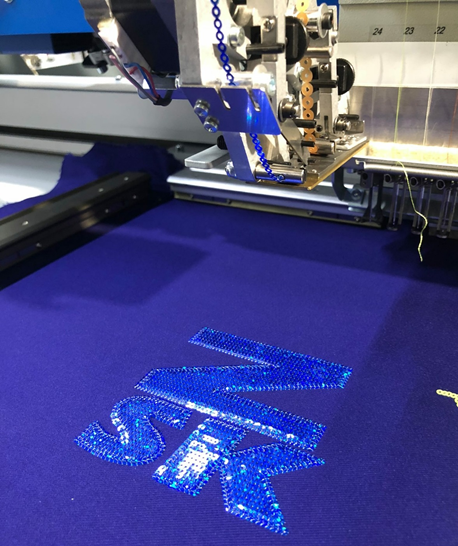

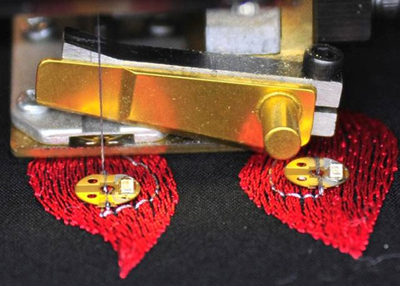

One innovative method of functionalizing fabrics in the field of technical textiles is the incorporation of embroidered LED sequins. This process involves mounting the necessary electronics onto a traditional sequin carrier and using an industrial embroidery machine to robotically sew the LED sequins into the fabric during its creation. This method offers significant advantages over other e-textile processes, as it eliminates the need for post-process soldering or the use of additional conductive epoxies.

Embroidered LED sequins exemplify the integration of electronics within textile structures, creating smart textiles that can react to environmental stimuli or user interaction. This integration is achieved through the precise control of the embroidery machine, which seamlessly incorporates electronic components into the fabric. By using conductive threads, the machine establishes electrical connections between the LEDs and the power source, often a small battery pack discretely housed within the garment.

Historically, the use of LEDs in textiles was limited due to the need for bulky wiring and separate power sources. However, with the advent of miniaturized electronics and advanced embroidery techniques, it is now possible to integrate LED sequins directly into the fabric structure, creating luminous textiles with various applications ranging from fashion and design to safety and communication.

The evolution of this technology can be traced back to early experiments with electroluminescent wires and fiber optics, which, while innovative, lacked the flexibility and comfort required for wearable applications. Today, embroidered LEDs offer a solution that is both aesthetically pleasing and functionally robust, opening new possibilities for interactive clothing, illuminated safety gear, and dynamic display textiles.

Figure 1: Embroidered LED sequin

Figure 2: LED sequin mounted on a traditional carrier

Figure 3: Robotic sewing of LED sequins into fabric

In this process, the embroidery machine serves as a hybrid between traditional pick and place machines, which select a component sequin off of a reel, and a sequin machine, as it stitches the component into the fabric’s structure. This represents a significant advancement in the field of e-textiles, combining the precision of automated machinery with the versatility of traditional embroidery techniques.

It's important to note that the quality of the final product is highly dependent on the machine settings, especially the thread tension, thread take-up lever, rotary hook, and bobbin case settings. These must be finely tuned to ensure consistent stitching and proper placement of the LED sequins.

The thread take-up lever is crucial as it ensures that the thread is correctly fed through the needle, preventing slack that could lead to uneven stitching or thread breakage. Similarly, the rotary hook, which captures the needle thread to form a stitch, must be precisely aligned to avoid skipped stitches. The bobbin case, holding the lower thread, must maintain consistent tension to ensure balanced stitching with the top thread.

Common mistakes include incorrect threading, improper tension settings, and misalignment of the LED components, all of which can lead to functional failures or aesthetic defects. Therefore, regular machine maintenance and calibration are essential for optimal performance.

Figure 4: Industrial embroidery machine

Learn More:

- ASTM Textile Standards

- ISO Standards

- Research Paper: Embroidery and related manufacturing techniques for wearable antennas

- Research Paper: Industrial embroidery for technical textiles