Embroidering full boards mechanically

Section outline

-

Technical Embroidery: An Introduction

Overview of Technical Embroidery

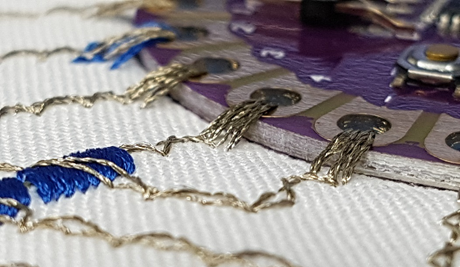

Technical embroidery refers to the integration of traditional embroidery techniques with modern digital technologies. This innovative practice has revolutionized the textile industry, particularly in the field of technical textiles and e-textiles. One of the most direct uses of technical embroidery is to quickly attach and stitch traditional printed circuit boards (PCBs) into fabric carriers.

Stitching PCBs directly into the structure of the textile, using components such as the thread take-up lever, rotary hook, and bobbin case, reduces mechanical strains on the connectors while allowing the control and processing electronics to be physically closer to their supporting electronics. The thread take-up lever plays a crucial role in maintaining thread tension, while the rotary hook is essential for creating the lockstitch by catching the top thread. The bobbin case holds the bobbin, ensuring smooth thread delivery. This technique can have a range of benefits such as increased signal-to-noise ratio, decreased mechanical fatigue-based failure, and reduced need for additional connectors. These advantages are particularly significant in applications where reliability and durability are critical, such as in medical devices or aerospace textiles.

The Electronics Packaging Standpoint

If looked at from an electronics packaging standpoint, fabrics offer a new host of materials that not only house the electronics but also provide functional advantages over traditional materials and processes. This is largely due to the inherent flexibility, breathability, and lightweight nature of textiles, which allows for the creation of more comfortable and wearable electronic devices. Moreover, textiles can be engineered to provide additional functionalities such as moisture-wicking, antibacterial properties, and thermal regulation, making them ideal for wearable technology applications.

Embroidery of Full Board Systems

Technical embroidery isn't limited to stitching individual components; full board systems can be embroidered with a wide variety of different off-the-shelf boards. This opens up a new realm of possibilities for the design and manufacture of electronic textiles, from smart clothing to wearable medical devices. By integrating sensors, actuators, and microcontrollers directly into the fabric, designers can create garments that monitor health metrics, provide feedback, or interact with the environment. This capability is particularly valuable in fields such as sports performance, health monitoring, and safety apparel.

Learn More

For further reading on the topics covered in this module, consider the following resources:

- Technical Embroidery for Smart Textiles - A research paper on ResearchGate

- ASTM Textile Standards - Standards from ASTM International

- ISO Standards Catalogue - Standards from the International Organization for Standardization

Note: Keep in mind that mastering industrial machine embroidery requires a blend of theoretical knowledge and practical skills. Always practice under the guidance of an experienced professional. Additionally, understanding the maintenance and troubleshooting of embroidery machines, including the proper handling of the thread take-up lever, rotary hook, and bobbin case, is essential for achieving high-quality results.