Introduction to Composites

Section outline

-

Introduction to Embroidery of Composite PreformsEmbroidery of composite preforms is a rapidly growing field, particularly driven by the trends of lightweighting in electric and autonomous vehicles within the automotive industry. Techniques such as Tailored Fiber Placement (TFP) enable fibers to be placed in net preform shapes, which simplifies construction and lowers costs. In this introductory course, we will explore the benefits of TFP and examine some of the strategies used to optimize these components effectively.

The Role of Carbon Fiber in Modern CompositesDespite the recent decrease in the cost of carbon fiber, it remains an expensive and highly sought-after material due to its exceptional properties. Carbon fiber composites are renowned for their high strength-to-weight ratio, making them ideal for the next generation of fuel-efficient transportation solutions. Reducing the weight of vehicles, aircraft, or spacecraft can significantly improve fuel efficiency over their operational lifetime. Consequently, carbon fiber is increasingly being considered as a replacement for aluminum in certain structural applications due to the substantial weight savings it offers. However, the high initial material costs of carbon fiber composites can deter potential adopters.

Challenges in Traditional Carbon Fiber ManufacturingThe manufacturing of traditional carbon fiber composites has historically required more processing involvement compared to metals like aluminum. Traditional processes often involve steps such as CAD tracing of woven carbon fiber fabrics, cutting them to scale, wetting them with matrix materials, and curing them into shape using methods like resin transfer molding (RTM). These processes tend to be labor-intensive and lack the automation found in competing metal processes such as milling or sheet metal bending.

Advantages of Tailored Fiber PlacementTailored Fiber Placement (TFP) offers a material and process-efficient method for creating new carbon fiber composite parts, significantly reducing costs. TFP reduces waste by optimizing the use of carbon fiber material, thereby lowering material costs. This technique allows for the integration of other fibrous materials in specific locations, tailoring fibers to specific loading conditions, and achieving variable thickness throughout the parts. Moreover, TFP can easily incorporate new classes of fibrous technical materials. The versatility of TFP machines, which require minimal retooling to produce vastly different parts from batch to batch, enhances the manufacturing process's adaptability. The optimizations provided by TFP can make carbon fiber composites increasingly cost-competitive.

SummaryIn summary, the embroidery of composite preforms, particularly through Tailored Fiber Placement, represents a significant advancement in the manufacturing of lightweight, high-performance components. By reducing material waste, increasing manufacturing flexibility, and enabling the integration of varied materials, TFP addresses some of the key challenges associated with traditional carbon fiber composite manufacturing. As the demand for fuel-efficient and lightweight vehicles continues to grow, the application of TFP in composite preform production will likely expand, offering a cost-effective alternative to traditional methods.

Further Reading & Resources- Composites World - Industry news and insights on composite materials.

- ZSK Technical Embroidery - Detailed information on Tailored Fiber Placement.

- JEC Composites - A platform dedicated to the composite materials industry.

-

Waste Reduction in Carbon Fiber Composites

One of the prevailing challenges in traditional carbon fiber composite manufacturing techniques is the significant material waste generated during production. In hand lay-up processes, which commonly use carbon fiber woven materials, waste can constitute over 50% of the total carbon fiber used. This waste primarily occurs during the initial cutting of fabric before it is impregnated with the matrix material. Furthermore, additional waste is generated during post-processing, where the cured composite is trimmed and refined to achieve the desired shape.

Tailored Fiber Placement Technique

Tailored Fiber Placement (TFP) is a revolutionary technique that significantly reduces material waste, thus optimizing material costs. Unlike traditional methods, TFP allows precise control over the path of the tow material, which is stitched directly into the desired geometry. This precision means that material is only placed where it is needed in the final preform. Areas that would typically require cutting in conventional laminate designs are simply left unstitched, effectively eliminating unnecessary waste.

By utilizing TFP, manufacturers can reduce initial waste from cutting woven fabrics and minimize post-processing waste due to its capability to conform to complex geometries. This process not only enhances material efficiency but also contributes to more sustainable manufacturing practices in the composites industry.

Applications and Advantages

The application of Tailored Fiber Placement is particularly advantageous in industries that demand high-performance composites with minimal waste, such as aerospace, automotive, and sports equipment manufacturing. The ability to design components with optimized fiber orientations and minimal waste leads to lighter, stronger, and more cost-effective products.

Moreover, TFP enables the creation of complex geometries with varying thicknesses and fiber orientations, which would be challenging or inefficient to produce using traditional methods. This flexibility in design and manufacturing makes TFP an attractive option for producing advanced composite components.

Further Reading & Resources

-

Traditional laminate processes in composite manufacturing often lack the flexibility to integrate multiple materials efficiently within a single structure. This limitation can lead to wasted resources and suboptimal performance characteristics. To address this, the technique of Tailored Fiber Placement (TFP) has been developed. TFP offers a method to strategically position different fibers within a composite, optimizing for specific mechanical properties where they are needed most.

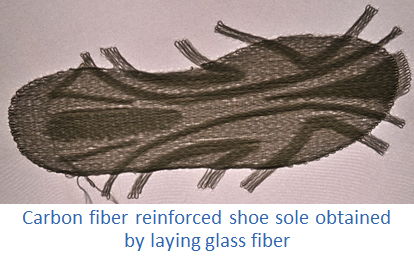

Consider a scenario where a structural component undergoes analysis, revealing that only certain regions require enhanced stiffness. In such cases, carbon fiber, known for its high stiffness-to-weight ratio, can be precisely positioned to reinforce these critical areas. This strategic placement avoids unnecessary use of expensive materials across the entire component, thereby reducing costs. For regions that do not require the same level of stiffness, more economical materials such as glass fiber or hemp fiber can be utilized. This transition between materials is seamless, thanks to the capabilities of tailored fiber placement.

Advantages of Tailored Fiber Placement

Tailored Fiber Placement offers several advantages over traditional composite manufacturing techniques:

- Material Efficiency: By using high-performance materials only where necessary, TFP reduces material waste and cost.

- Structural Optimization: Enhances the mechanical performance by placing fibers in optimal orientations and locations.

- Design Flexibility: Allows for complex geometries and varying material properties within a single component.

- Environmental Impact: By incorporating sustainable fibers like hemp, TFP can reduce the environmental footprint of composite manufacturing.

Applications in Industry

TFP is increasingly being adopted across various industries due to its ability to produce lightweight, high-strength components. Some applications include:

- Aerospace: Used in aircraft structures where weight reduction is critical.

- Automotive: Applied in the production of lightweight, fuel-efficient vehicles.

- Sports Equipment: Utilized in high-performance sports gear like bicycles and tennis rackets.

- Renewable Energy: Employed in the construction of wind turbine blades for optimized performance.

Further Reading & Resources

-

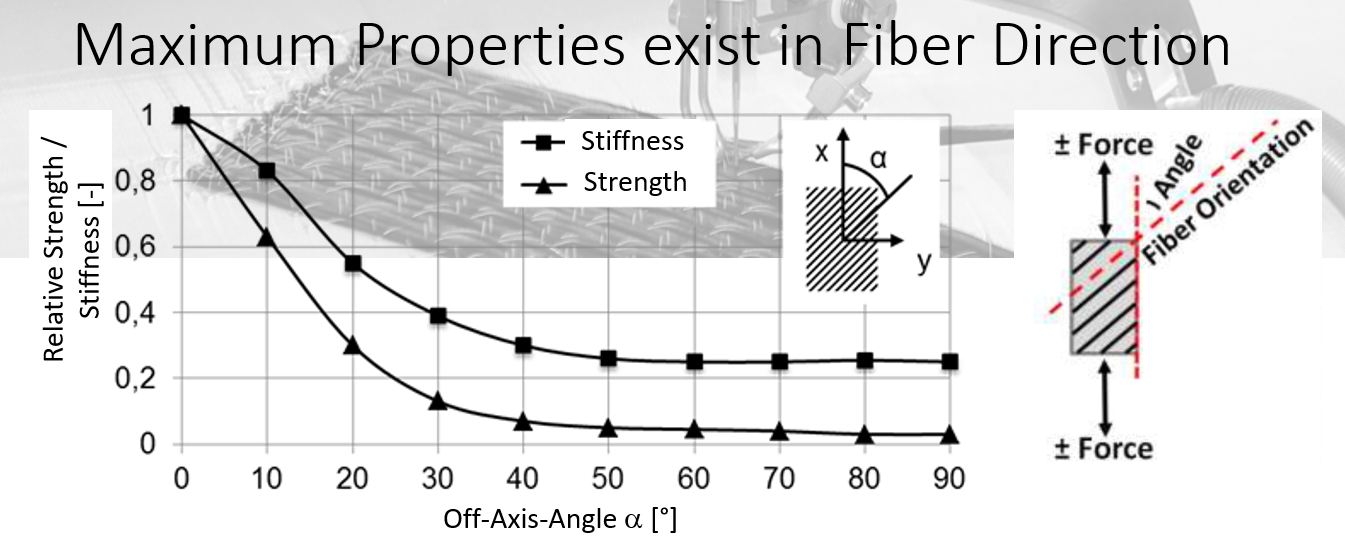

One of the most significant advantages of using Tailored Fiber Placement (TFP) in composite design is the ability to precisely control the placement of each tow of carbon fiber. This precision allows designers to optimize material properties effectively, minimizing the need for excess material while maintaining structural integrity. By strategically placing fibers, designers can enhance the performance of composite structures, reducing weight and material costs while achieving desired mechanical properties.

In the study by K. Uhlig et al., titled "Meso-scaled finite element analysis of fiber reinforced plastics made by Tailored Fiber Placement," published in Composite Structures, Volume 143, 2016, Pages 53-62, the authors explore the benefits of TFP in enhancing the performance of fiber-reinforced plastics. The study provides insights into the meso-scale modeling of these materials, highlighting the significant improvements in strength and durability achieved through this advanced placement technique. For more details, you can access the study here.

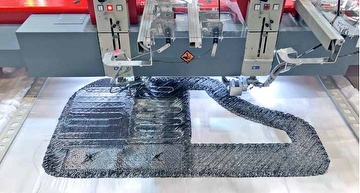

An example of TFP's application is in the creation of complex tow paths of carbon fiber that are specifically embroidered to resist applied loads effectively. By aligning fibers with the principal stresses, the design provides additional mechanical support without the need for additional material. This method is particularly advantageous for reinforcing areas prone to stress, such as holes and circular drill points. In traditional laminate designs, these areas can become crack propagation sites due to the orthogonal nature of woven fabrics. However, with TFP, fibers can be strategically placed in curvilinear patterns around these points, significantly reducing potential crack initiation sites. This technique allows for thinner material usage at these critical locations and may even eliminate the need for metal reinforcing washers.

Further Reading & Resources

To explore more about Tailored Fiber Placement and its applications, consider the following resources:

- ScienceDirect: Composite Structures Journal - A comprehensive resource for research articles related to composite materials and their applications.

- ResearchGate: Meso-scaled Finite Element Analysis - Access additional research on TFP and its impact on material performance.

-

Tailored fiber placement (TFP) in carbon fiber composites offers a significant advantage through the optimization of tunable thickness across a given area. Unlike traditional laminate designs, which assume a uniform thickness, TFP allows for variable thicknesses, enabling enhanced structural performance. This approach, when paired with carefully designed molding and fixtures, allows carbon fiber preforms to achieve localized thickness variations across complex geometries. In classical beam theory, the moment of inertia \( I \) for a rectangular beam is calculated by:

\[ I = \frac{b \cdot h^3}{12} \]

Here, \( h \) represents the height of the material and has a cubic influence on the moment of inertia, whereas \( b \) is the base length. This indicates that increasing the thickness in specific areas significantly enhances the material's resistance to bending. Consequently, tailored fiber placement can optimize material usage by concentrating thickness where it is most needed, achieving improved mechanical properties with less material compared to traditional composite processes.

Advanced machinery, such as those offered by ZSK, can lay fibers with a thickness of up to 8 mm, equivalent to approximately eight layers of 50K carbon fiber roving. This thickness can be uniformly applied across the preform or strategically placed in key structural areas to provide additional mechanical support where necessary.

In the example above, thickness is strategically increased around the perimeter and center of the component. This additional thickness enhances the part's ability to withstand bending moments, while reducing material costs by avoiding unnecessary reinforcement in areas that do not require it. Furthermore, the curvilinear placement of fibers around holes minimizes crack propagation, a common issue in orthogonal woven sheet laminate designs, and reduces waste and post-processing requirements.

Further Reading & Resources

For more in-depth information, consider exploring the following resources:

- ZSK Technical Embroidery Systems - Learn more about advanced embroidery and fiber placement machinery.

- ScienceDirect: Tailored Fiber Placement - A detailed study on the applications and benefits of TFP in composite manufacturing.

- Composites World: Tailored Fiber Placement - An article discussing the latest innovations and trends in TFP.

-

One of the drawbacks of traditional composite laminate manufacturing is the extended cycle times required to properly cure a thermoset resin. These lengthy processes often impede productivity and increase costs in industrial applications. To address this, new materials known as comingled fibers have been developed to decrease processing time significantly. In comingled fibers, a carbon fiber tow incorporates additional thermoplastic matrix materials directly into its fiber structure. This innovation not only enhances manufacturing efficiency but also offers new possibilities for composite material applications.

These comingled materials can be stitched using techniques similar to those applied in other tailored fiber placement composite materials. The advantage of using comingled fibers lies in their ability to be rapidly thermocycled in heated presses, which dramatically reduces the cycle processing time. Traditional thermoset composite materials, when processed using resin transfer molding, can require curing times ranging from 30 minutes to as long as 40 hours to properly set and cure a single piece. In contrast, comingled fibers streamline this process, offering substantial time savings and operational efficiencies.

Tailored fiber placement of comingled materials enables the concurrent placement of both the reinforcing fiber and the matrix material within the same preform. As the preform is heated, the thermoplastic matrix material melts and is distributed seamlessly into the carbon fiber, ensuring proper wetting and adhesion. This method eliminates the need for additional resins, which not only reduces material costs but also minimizes the potential for voids and defects in the final composite. Moreover, the desired fiber-to-volume fraction is established during the comingling step, enhancing the uniformity and consistency of the composite material across different production batches.

Finally, these comingled fiber composites represent a step towards more sustainable carbon fiber composites due to their ability to be re-melted and reformed into new shapes at the end of their lifecycle. This reusability aligns with modern sustainability goals by reducing waste and promoting the recycling of composite materials, thereby contributing to a more circular economy.

Further Reading & Resources

-

Another significant process optimization that occurs with tailored fiber placement (TFP) compared to other composite manufacturing processes is the machine's ability to rapidly switch production from one design to a completely different design without the need for additional retooling. This flexibility allows manufacturers to maximize machine utilization and adapt quickly to changing production needs. For instance, the same machine can seamlessly transition from producing automotive components during the morning shift to manufacturing sporting equipment in the afternoon. This adaptability not only enhances production efficiency but also reduces downtime, leading to cost savings and increased throughput.

Furthermore, tailored fiber placement technology supports the creation of single prototype designs for process investigation and troubleshooting without incurring excessive material waste. This capability is particularly beneficial in the research and development phase, where iterative testing and refinement are crucial. Once the prototype is validated, the same machine can transition seamlessly to full-scale production. The rapid prototyping-to-production capability, combined with the machine's ability to handle various part types and geometries in quick succession, enables more versatile project execution. This versatility reduces the need for setting up new machinery with each new design iteration, significantly lowering the setup costs and time associated with new product development.

Summary

Tailored fiber placement offers a transformative approach to composite manufacturing by providing rapid design switching capabilities and supporting efficient prototyping-to-production transitions. This technology enables manufacturers to respond swiftly to market demands and innovate without the traditional constraints of retooling and setup time. The economic and operational benefits of TFP make it a valuable asset in industries such as automotive, aerospace, and sports equipment manufacturing, where flexibility and speed are paramount.

Further Reading & Resources

-

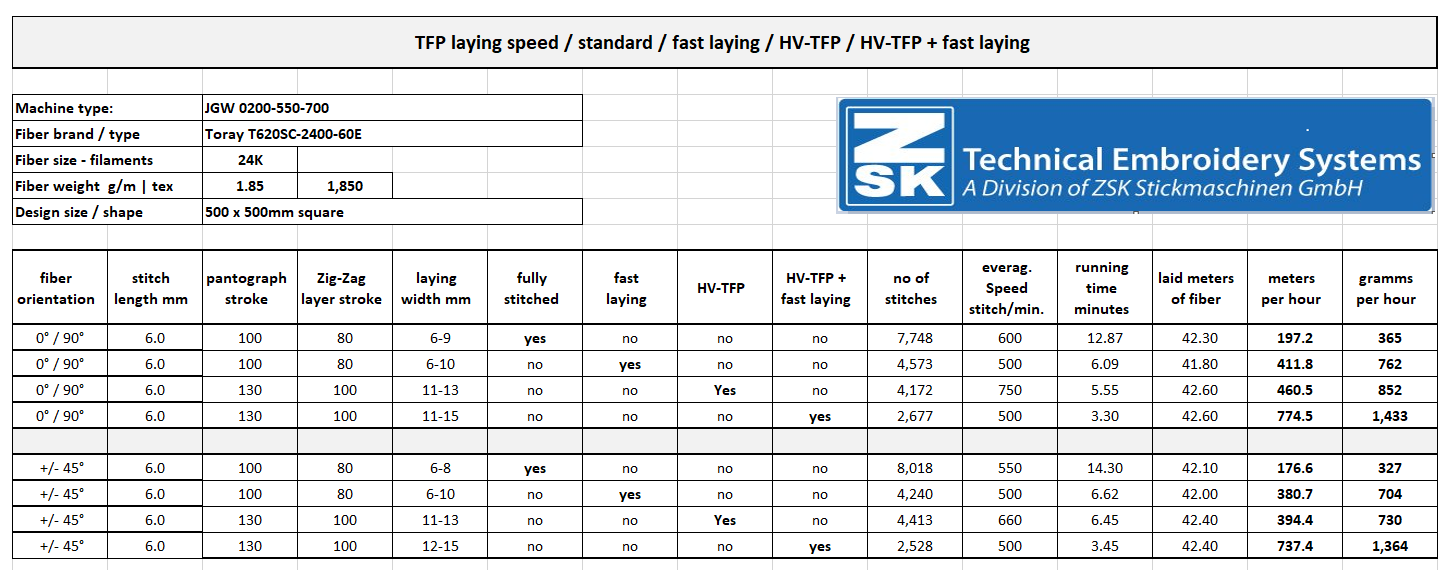

Layering Speed:

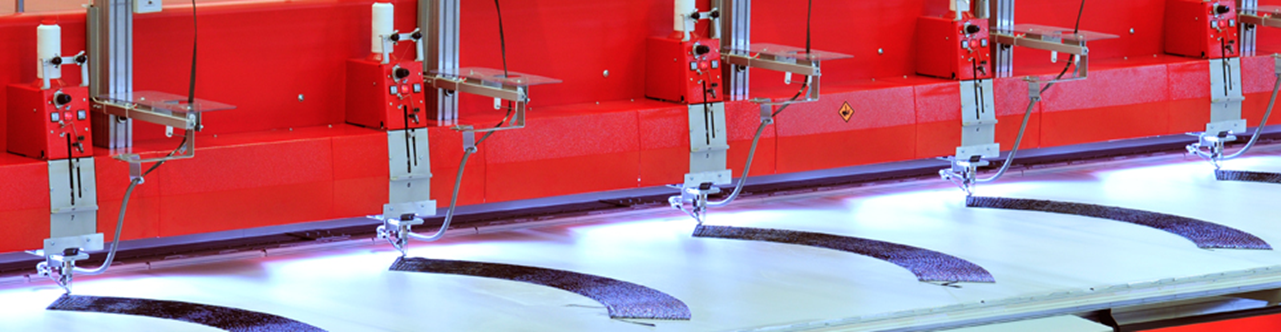

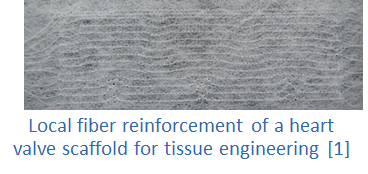

The innovative field of technical embroidery is continually expanding, with new applications for composites emerging regularly. The ZSK Research and Training Center plays a pivotal role in this development, consistently pushing the boundaries of what is achievable in the realm of technical textiles. By integrating advanced techniques and materials, they are revolutionizing how we think about and use composites.

A large-sized car door panel made with Tailored Fiber Placement (TFP) carbon fiber includes integrated heating wires, cabling, and metal inserts. These components are crucial for attaching additional parts to the carbon structure, enhancing the functionality and integration of electronic systems within automotive applications.

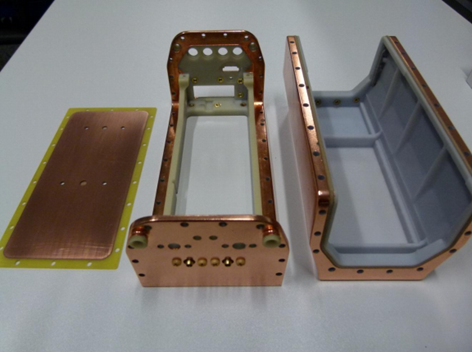

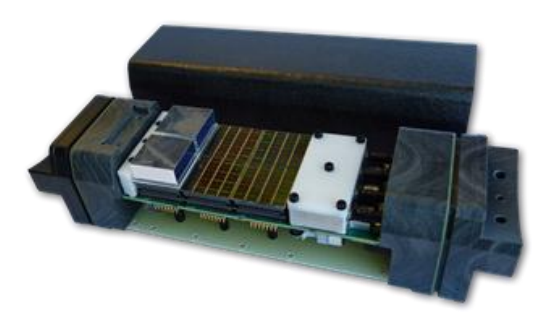

In the medical imaging sector, electromagnetic shielding is essential, particularly in combination PET/MRI devices. Traditionally, copper has been used for this purpose, but it presents cost and quality challenges. By incorporating embroidered carbon fiber, these issues can be mitigated. Carbon fiber provides an effective alternative, offering superior electromagnetic interference (EMI) shielding, reduced weight, and lower production costs.

Anderson, T. (2013). Fabrication and characterization of carbon fiber composite-based electromagnetic interference shielding for simultaneous PET/MRI. Master’s Thesis, RWTH Aachen University, Aachen, Germany.

[1] Hörr, M. ITA - Institut für Textiltechnik, Aachen University, Germany, 2014.

Further Reading & Resources

To deepen your understanding of technical embroidery and its applications in modern composites, consider exploring the following resources:

- ZSK Technical Embroidery - Learn more about the latest advancements and technologies in technical embroidery.

- Institut für Textiltechnik, Aachen University - Explore research and publications on technical textiles and composites.

- ScienceDirect: Carbon Fiber - A comprehensive overview of carbon fiber materials and their applications.

-

In conclusion, the six methods of optimization for carbon fiber composites illustrate the significant advantages of tailored fiber placement (TFP) over traditional composite processes. TFP allows for precise control over fiber orientation and placement, which enhances the mechanical properties of the composite material. By optimizing the load paths and reducing waste, TFP contributes to more efficient and sustainable manufacturing processes. As carbon fiber material costs continue to decrease, the adoption of these advanced techniques is expected to expand, further improving consumer applications, such as increasing fuel efficiency in automotive and aerospace industries.

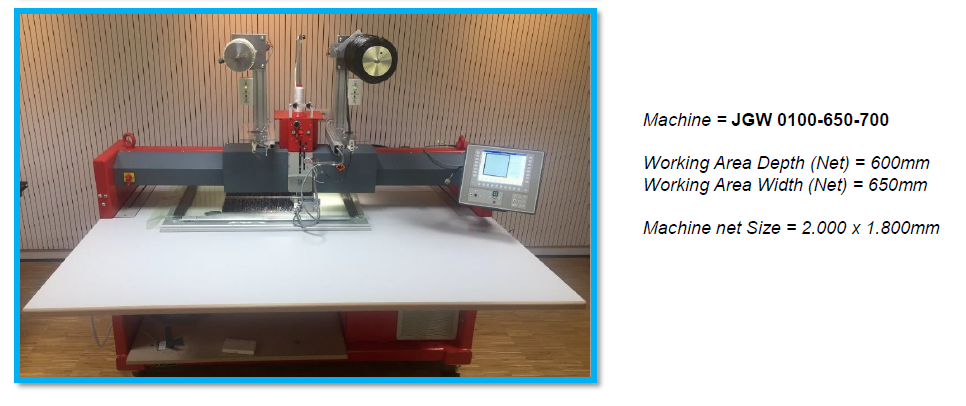

ZSK offers a range of machines designed for tailored fiber placement, accommodating various part sizes and manufacturing scenarios. Their prototyping machines, equipped with a single head, are ideal for rapid development and experimentation with new materials, requiring minimal setup time and resource investment. These machines are perfect for exploring combinations of materials such as carbon fiber and glass fiber within a compact working area of 0.6m x 0.65m.

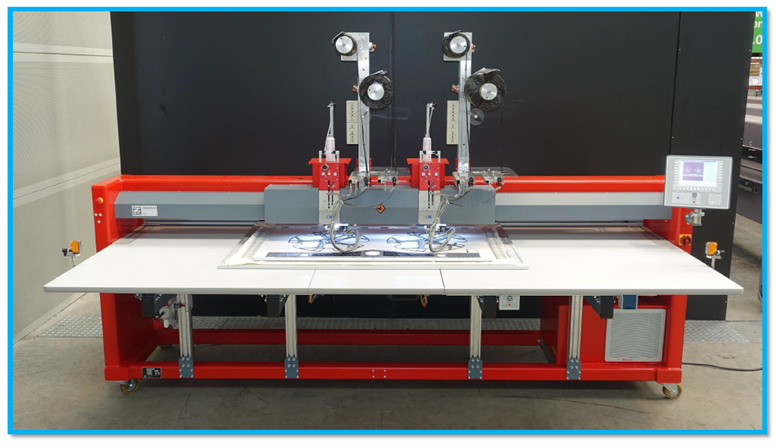

For mass production, ZSK provides machines with up to 11 heads, enabling simultaneous fiber placement across multiple parts. An 8-head machine, for example, offers a working area of 900 mm x 1,900 mm per head. This configuration allows the creation and duplication of parts up to 8 times in a single run, provided each part fits within the specified dimensions.

The single-head JGW machine is an excellent entry point into the composites industry. It supports fast material exploration within a working area of 0.6m x 0.65m, accommodating two materials simultaneously, such as carbon fiber and glass fiber. This flexibility is crucial for developing innovative composite solutions.

For larger components, an 8-head machine can be easily reconfigured into a 4-head extended machine, increasing the maximum part size to 1,800 mm x 1,900 mm. This adaptability allows for the production of larger parts without significant downtime. Additionally, ZSK offers customizable solutions, including roll-to-roll systems and specialty placement machines, to meet diverse production needs.

The two-headed JGW machine enhances production efficiency by enabling the simultaneous creation of two smaller parts. One of the heads can be deactivated to allow for the fabrication of a larger single part, highlighting the machine's flexibility. This model is widely used for composites prototyping due to its versatility and efficiency.

Machine = JGW 0200-550D-700

Head Number = 2

Head Distance = 900 mm

Working Area Depth (Net) = 1,200 mm

Working Area Width (Net) = 8 x 900 mm or 4 x 1,800 mm

Machine Net Size = 11,560 x 3,460 mm

The CZCW machine is a full-sized production unit that can be configured with different levels of automation to suit specific composite production line requirements. It is designed to efficiently handle large-scale manufacturing tasks, offering substantial throughput and consistency.

Machine = CZCW 0800-900D-2000

Head Number = 8

Head Distance = 900 mm

Working Area Depth (Net) = 1,900 mm

Working Area Width (Net) = 8 x 900 mm or 4 x 1,800 mm

Machine Net Size = 11,560 x 4,460 mm

Further Reading & Resources

-

Tailored Fibre Placement (TFP) in Composite Materials

Tailored Fibre Placement (TFP) is an advanced manufacturing technique used in the field of composite materials. This method involves the strategic placement of fiber tows or rovings onto a substrate, allowing for precise control over fiber orientation and distribution. The TFP process enhances the mechanical properties of composite structures, such as strength, stiffness, and damage resistance, by aligning fibers along the principal stress directions.

Applications of Tailored Fibre Placement

TFP is particularly effective in applications requiring local reinforcement, such as open-hole tension plates made from carbon/epoxy laminates. By optimizing the fiber layout, stress concentrations around holes or notches can be minimized, significantly improving the structural integrity and performance of the material. This technique is widely used in aerospace, automotive, and sports equipment industries where high-performance composites are critical.

For instance, the application of TFP in thermoplastic composites has been explored to enhance the mechanical properties and reduce weight in automotive components, leading to better fuel efficiency and reduced emissions.

Technical Considerations

The TFP process involves several technical considerations, including:

- Material Selection: Choosing the appropriate fiber and matrix materials to achieve desired mechanical properties.

- Design Optimization: Using computer-aided design (CAD) tools to model stress distribution and optimize fiber paths accordingly.

- Manufacturing Precision: Employing automated machines to ensure accurate fiber placement and alignment.

Mathematically, the effectiveness of TFP can be evaluated by analyzing stress distribution using finite element analysis (FEA), which models how applied loads affect the composite structure.

Innovative Techniques and Industry Trends

Recent advancements in TFP have introduced innovative techniques for enhancing damage resistance and reducing material waste. The integration of TFP with additive manufacturing technologies allows for the creation of complex composite designs at a rapid pace, making it a valuable asset in the production of lightweight, high-strength components.

Moreover, the use of TFP in smart textiles is gaining traction, where conductive fibers are strategically placed to create flexible electronic circuits within the fabric. This opens up new possibilities in wearable electronics, such as health monitoring garments and interactive clothing.

Further Reading & Resources

- Application of the tailored fibre placement (TFP) process for a local reinforcement on an “open-hole” tension plate from carbon/epoxy laminates

- Tailored fibre placement to minimise stress concentrations

- Tailored Fiber Placement in Thermoplastic Composites

- Tailored Fiber Placement in Thermoplastic Composites

- Innovative tailored fiber placement technique for enhanced damage resistance in notched composite laminate

- Tailored fibre placement of carbon fibre rovings for reinforced polypropylene composite part 1: PP infusion of carbon reinforcement

- Tailored Fibre Placement – complex composite designs delivered at speed with reduced waste

-

Further Reading & Resources

- Composites World

- ZSK Technical Embroidery

- JEC Composites

- Composites World: Tailored Fiber Placement

- ScienceDirect: Tailored Fiber Placement

- ResearchGate: Tailored Fiber Placement (TFP)

- Composites World: Tailored Fiber Placement

- ResearchGate: Tailored Fiber Placement (TFP) - Opportunities and Challenges

- here

- ScienceDirect: Composite Structures Journal

- ResearchGate: Meso-scaled Finite Element Analysis

- ZSK Technical Embroidery Systems

- ScienceDirect: Tailored Fiber Placement

- Composites World: Tailored Fiber Placement

- Thermoplastic composites: A gaining foothold

- ScienceDirect: Comingled Fiber

- Comingled Fibers: A New Twist on Thermoplastic Composites

- Advances in Tailored Fiber Placement for Composite Structures

- Tailored Fiber Placement: Advantages for Composite Structures

- Institut für Textiltechnik, Aachen University

- ScienceDirect: Carbon Fiber

- ZSK Technical Embroidery Systems

- ScienceDirect: Tailored Fiber Placement

- Application of the tailored fibre placement (TFP) process for a local reinforcement on an “open-hole” tension plate from carbon/epoxy laminates

- Tailored fibre placement to minimise stress concentrations

- Tailored Fiber Placement in Thermoplastic Composites

- Tailored Fiber Placement in Thermoplastic Composites

- Innovative tailored fiber placement technique for enhanced damage resistance in notched composite laminate