Machine Options

Section outline

-

In conclusion, the six methods of optimization for carbon fiber composites illustrate the significant advantages of tailored fiber placement (TFP) over traditional composite processes. TFP allows for precise control over fiber orientation and placement, which enhances the mechanical properties of the composite material. By optimizing the load paths and reducing waste, TFP contributes to more efficient and sustainable manufacturing processes. As carbon fiber material costs continue to decrease, the adoption of these advanced techniques is expected to expand, further improving consumer applications, such as increasing fuel efficiency in automotive and aerospace industries.

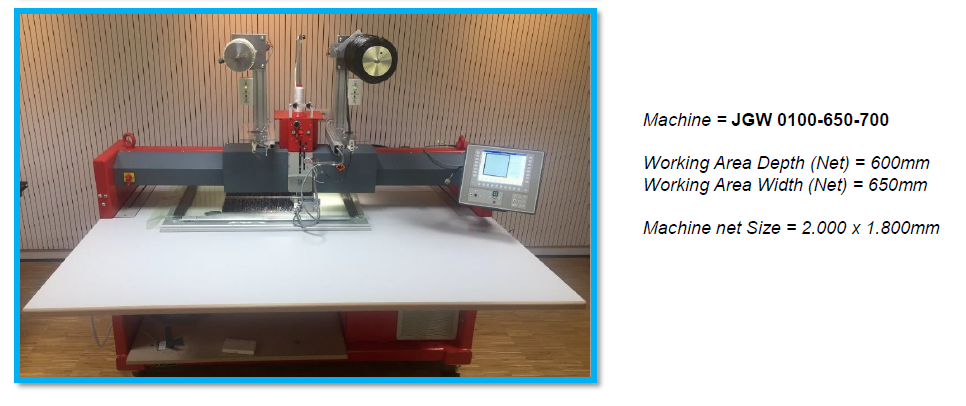

ZSK offers a range of machines designed for tailored fiber placement, accommodating various part sizes and manufacturing scenarios. Their prototyping machines, equipped with a single head, are ideal for rapid development and experimentation with new materials, requiring minimal setup time and resource investment. These machines are perfect for exploring combinations of materials such as carbon fiber and glass fiber within a compact working area of 0.6m x 0.65m.

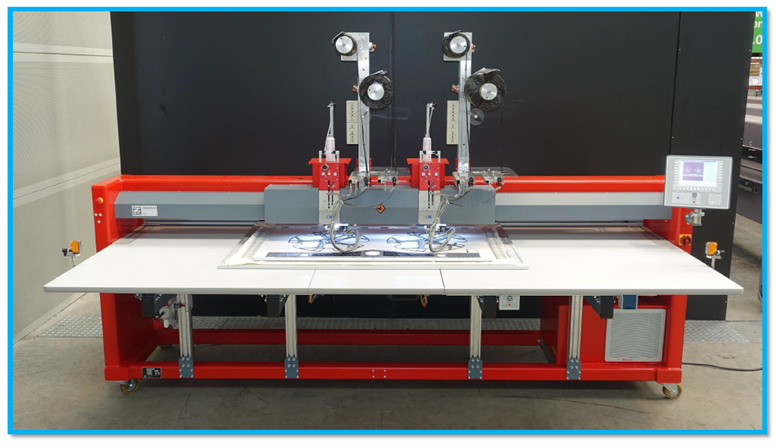

For mass production, ZSK provides machines with up to 11 heads, enabling simultaneous fiber placement across multiple parts. An 8-head machine, for example, offers a working area of 900 mm x 1,900 mm per head. This configuration allows the creation and duplication of parts up to 8 times in a single run, provided each part fits within the specified dimensions.

The single-head JGW machine is an excellent entry point into the composites industry. It supports fast material exploration within a working area of 0.6m x 0.65m, accommodating two materials simultaneously, such as carbon fiber and glass fiber. This flexibility is crucial for developing innovative composite solutions.

For larger components, an 8-head machine can be easily reconfigured into a 4-head extended machine, increasing the maximum part size to 1,800 mm x 1,900 mm. This adaptability allows for the production of larger parts without significant downtime. Additionally, ZSK offers customizable solutions, including roll-to-roll systems and specialty placement machines, to meet diverse production needs.

The two-headed JGW machine enhances production efficiency by enabling the simultaneous creation of two smaller parts. One of the heads can be deactivated to allow for the fabrication of a larger single part, highlighting the machine's flexibility. This model is widely used for composites prototyping due to its versatility and efficiency.

Machine = JGW 0200-550D-700

Head Number = 2

Head Distance = 900 mm

Working Area Depth (Net) = 1,200 mm

Working Area Width (Net) = 8 x 900 mm or 4 x 1,800 mm

Machine Net Size = 11,560 x 3,460 mm

The CZCW machine is a full-sized production unit that can be configured with different levels of automation to suit specific composite production line requirements. It is designed to efficiently handle large-scale manufacturing tasks, offering substantial throughput and consistency.

Machine = CZCW 0800-900D-2000

Head Number = 8

Head Distance = 900 mm

Working Area Depth (Net) = 1,900 mm

Working Area Width (Net) = 8 x 900 mm or 4 x 1,800 mm

Machine Net Size = 11,560 x 4,460 mm

Further Reading & Resources