Optimization six: machine versatility without retooling

Section outline

-

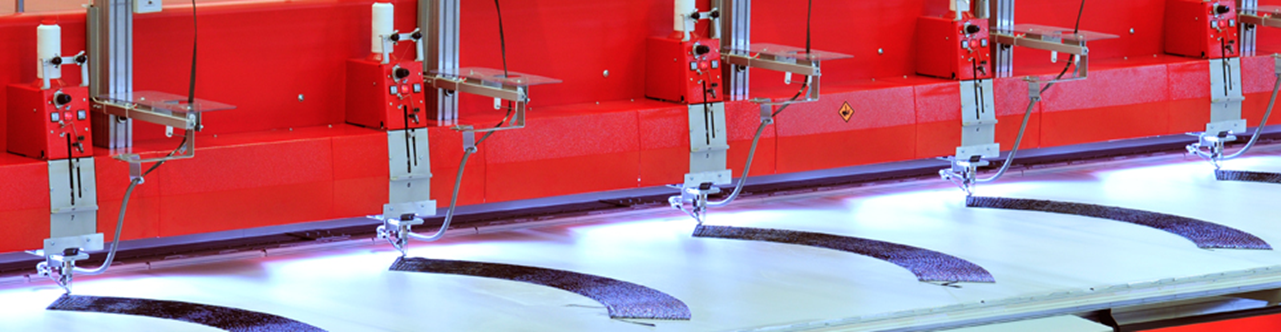

Another significant process optimization that occurs with tailored fiber placement (TFP) compared to other composite manufacturing processes is the machine's ability to rapidly switch production from one design to a completely different design without the need for additional retooling. This flexibility allows manufacturers to maximize machine utilization and adapt quickly to changing production needs. For instance, the same machine can seamlessly transition from producing automotive components during the morning shift to manufacturing sporting equipment in the afternoon. This adaptability not only enhances production efficiency but also reduces downtime, leading to cost savings and increased throughput.

Furthermore, tailored fiber placement technology supports the creation of single prototype designs for process investigation and troubleshooting without incurring excessive material waste. This capability is particularly beneficial in the research and development phase, where iterative testing and refinement are crucial. Once the prototype is validated, the same machine can transition seamlessly to full-scale production. The rapid prototyping-to-production capability, combined with the machine's ability to handle various part types and geometries in quick succession, enables more versatile project execution. This versatility reduces the need for setting up new machinery with each new design iteration, significantly lowering the setup costs and time associated with new product development.

Summary

Tailored fiber placement offers a transformative approach to composite manufacturing by providing rapid design switching capabilities and supporting efficient prototyping-to-production transitions. This technology enables manufacturers to respond swiftly to market demands and innovate without the traditional constraints of retooling and setup time. The economic and operational benefits of TFP make it a valuable asset in industries such as automotive, aerospace, and sports equipment manufacturing, where flexibility and speed are paramount.

Further Reading & Resources